Brand Name: HTEG

Model Number: CFB boiler

Place of Origin: Shandong, China (Mainland)

Thermal power plant 220t/h CFB boiler replacement parts from China

Introduction

We are one of the manufacturers of boiler and boiler parts in China. We have a team of engineers who have more than 20 years experience in designing, manufacturing, engineering, supplying of boiler and its spare parts. We manufacture CFB boiler, enameled corrugated plate, enameled tubular air preheater, rotary air preheater, H-finned tube economizer, spiral finned tube economizer, membrane water wall, header and other customized boiler parts.

CFB Boiler replacement parts

1.Enamelled tube for boiler air preheater

2.Enamelled tubular air preheater

Our company has over 20 years experience in researching, manufacturing and operating in the business of boiler air preheater products and has set up the R&D center for enamel heat exchanger parts( enamel tubes and enamel corrugated plate), which is the exclusive one in utility industry in China. We are the domestic leader in terms of technology in low temperature corrosion, abrasion resistance and ash fouling resistance for enamel tube air preheaters.

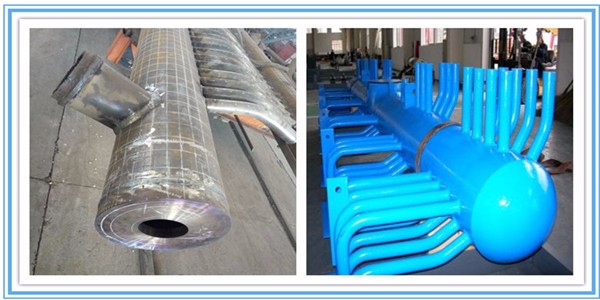

3.Finned tube Economzier

Economizer coils are used in downstream of Boiler bank to preheat the feed water absorbing heat from hot exhaust gases. Feed water can be heated up to a level about 20 - 30 C below saturation temperature of the boiler. Special care is taken for ovality and thinning at the bent portion, during fabrication. We manufacture Coils in Carbon steel with cold bending machine and with butt welding of tubes.

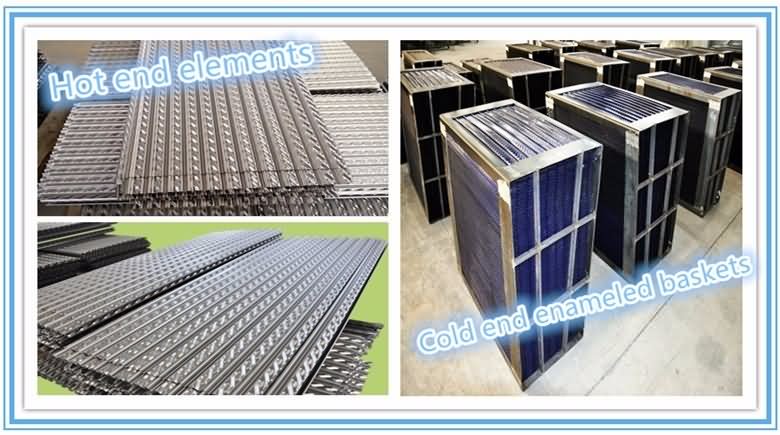

4.Enamelled heating elements

To solve the problem of corrosion to air preheater at low temperature environment and ash fouling, our company has developed a new kind enamel glaze with anti-abrasion, anti-corrosion, and less fouling features.

5.Superheater and reheater

In the boiler, the role of superheater is to heat the saturated steam to a certain temperature of superheated steam to increase power plant efficiency. Repeater essentially further improves the thermal power plant cycle efficiency.

6.Boiler distribution header

Steam header is the main equipment of boiler for allocating the steam to the all pipe. Steam header is a Pressure Vessel; the main function is to allocate steam. So steam header has many valves to connect the boiler main steam valve and steam distribution valve, and make the steam into anywhere.

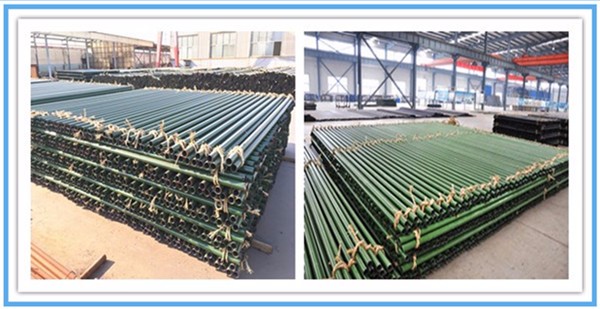

7. Boiler membrane waterwall panels

Water Wall Panels are used in modern day Boilers in place of Steam Generating Tubes to reduce heat loss due to their gas tight nature and reduce insulation costs. We fabricate Water Wall Panels using automatic Fin to tubes welding machines and large Tube Panel Benders to achieve desired shape of panels which can have Swaged Ends, Stub Welded to Headers. We supply Panels with integrated manhole openings in the panels.

Service range

We offer the following solutions:

1. Improvement based: fuel change, capacity enhancement, efficiency improvement

2. Solution based: solving steam temperature problems, repeated failures in particular area, removing operational limitations

Control & instrumentation modernization

Workshop and equipment

Customzers

Certifications

Our Qualification: Grade A boiler manufacturing; installation and contract of electromechanical equipment; EPC qualification for electric power engineering construction; installation, transformation and maintenance qualification of Grade 1 boiler and A2 pressure vessel manufacturing.

We have ISO 9001, ISO 14001 certificates.

We conform to ASME standard.

Cases

DONGFANG BOILER GROUP CO., LTD: heating elements for 60MW units boiler

HARBIN BOILER COMPANY LIMITED

SHANGHAI ELECTRIC

Contacts