Brand Name: HTEG

Model Number: Air preheater

Place of Origin: Shandong, China (Mainland)

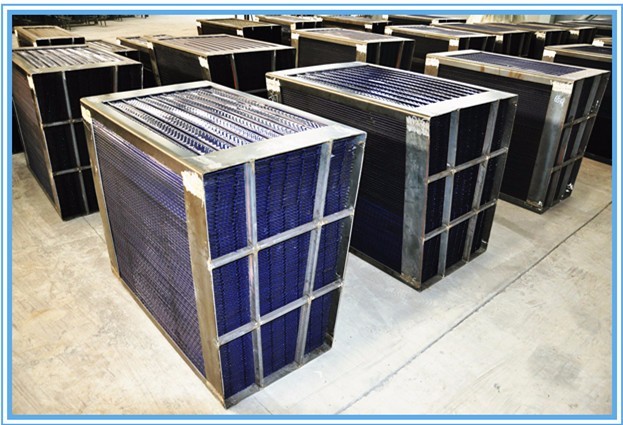

Boiler combustion tubular air preheater for boiler in thermal power

Introduction

Counted on our professional knowledge, we cater to the needs from customers in renovation and modernization of their exsiting boilers. We have undertaken boiler air preheater and economzier replacement service for many years.

Low temperature corrosion and ash fouling exists for boiler air preheater, especially if burning coal with high sulfur content. The users have to replace the parts or stop the machine to clean the ash, which takes cost for users. We adopted the enamel coated air preheater, which has the function of anti-corrosion, wear resistance, anti-ash fouling, and long service life.

We provide solution to the above problem by developing enameled air preheater.

Specifications

| Name | Boiler combustion tubular air preheater for boiler in thermal power |

| Material | Carbon steel or equivalent |

| Structure | vertical |

| Tubes | enameled seam or seamless tubes |

| Tube OD | as required |

| Enamel thickness | 0.34+/-0.06mm |

| Size | Customzied design |

Description

Our company has over 20 years experience in researching, manufacturing and operating in the business of boiler air preheater products and has set up the R&D center for enamel heat exchanger parts( enamel tubes and enamel corrugated plate), which is the exclusive one in utility industry in China. We are the domestic leader in terms of technology in low temperature corrosion, abrasion resistance and ash fouling resistance for enamel tube air preheaters.

Enamel air preheater products are classified as following by application:

1. Enameled air preehater designed for denitration renovation projects

2. Enameled air preheater for circulating fluidized bed boiler and pulverized coal boiler

3. Enameled air preheater for garbage incinerators and biomass boilers

4. Enameled air preheater for grate furnaces, like chain grate furnaces

5. Heat exchanger parts for gas-fueled boilers, such as kerosene boilers, coke ovens, etc.

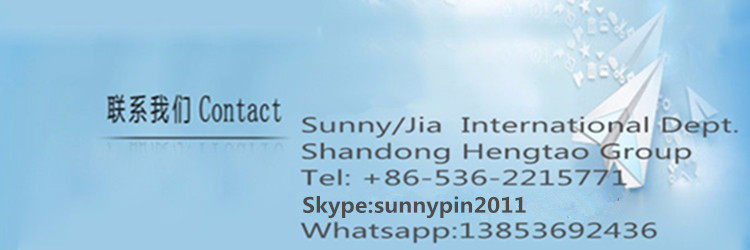

The accessory and detailed pictures

Parts:

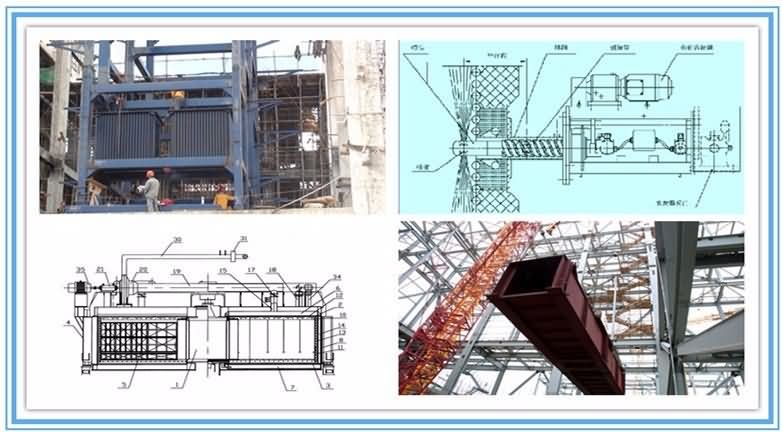

A: enamleded tubes: 1) external side enameled tubes 2). internal side enameled tubes 3) spiral grooved tubes

B: air preheater tubes sheet

C: air preheater tube chamber

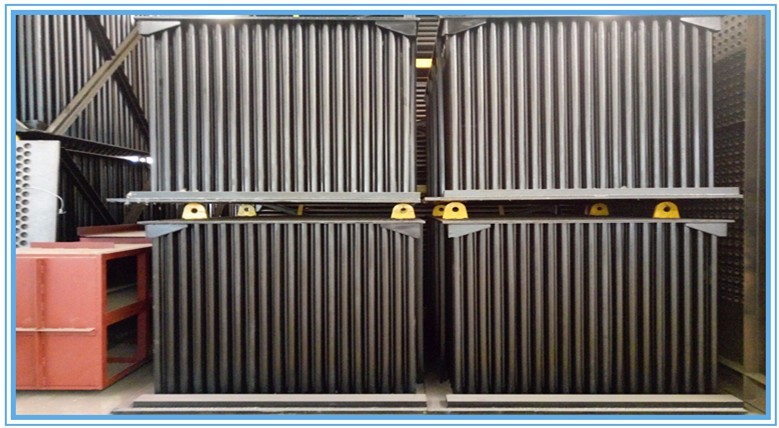

Application show

Low temperature corrosion and ash fouling exists for boiler air preheater, especially if burning coal with high sulfur content. The users have to replace the parts or stop the machine to clean the ash, which takes cost for users.

We adopted the enamel coated air preheater, which has the function of anti-corrosion, wear resistance, anti-ash fouling, and long service life.

Other hot products

Our company

We are one of the manufacturers of boiler and boiler parts in China. We have a team of engineers who have more than 20 years experience in designing, manufacturing, engineering, supplying of boiler and its spare parts. We manufacture CFB boiler, enameled corrugated plate, enameled tubular air preheater, rotary air preheater, H-finned tube economizer, spiral finned tube economizer, membrane water wall, header and other customized boiler parts

Packing & shipment

Customer visits

Customers from worldwide come to visit our factory and find the suitable products in our company.

Certificates

1. We have ISO 9001 certificate

2. ISO14001 certificate

3. ASME standard

4. TUV & BV certified supplier

Contact us