Brand Name: HTEG

Model Number: Customized

Place of Origin: Shandong, China (Mainland)

Heat exchanger stainless steel spiral fin tube made by forming machine is the most widely used of the spiral finned tube, widely used in electric power, metallurgy, cement industry preheating collection and petrochemical industries. High-frequency spiral finned tube is welded steel strip coil pipe at the same time, using high-frequency currents of the skin effect and proximity effect of steel tube, and surface heat until melted in the plastic state or steel strip coil, the complete welding under certain pressure. This kind of high frequency welding as a solidphase welding. It with Mosaic, brazing (or whole galvanized) method, whether in product quality (fin of weld rate is high, of 95%), or the productivity and automation degree, are more advanced.

Parameter

Name |

Heat exchanger stainless steel spiral fin tube made by forming machine |

Standard |

ASME SA213/ASTM A213,ASME SA106/ASTM A106,ASME SA179/ASTM A179,ASTM B111 |

Base Tube Material |

stainless steel, carbon steel, copper alloy,alloy steel (No theoretical limit) |

Fin Material |

Aluminium,Copper Alloy,Stainless Steel,Carbon Steel |

Fin tube Max design temperature |

<450°C |

Base pipe O.D |

25-165mm |

Fins per inch |

20 Nos(as customer's request) |

Fin depth |

0.5-3mm |

No fin area on both side |

As Customer's request. |

Design Temperature |

Below 450°C |

Product processing |

Extruded,Embedded,High Frequency Welding etc. |

Ends |

PE/Plain Ends, BE/Beveled Ends |

Test Requirement |

Physical Property Test,Chemical Composition Analysis,Non-Destructive Test,Other Inspection and |

Application |

Air Cooler,Charge Air Chiller, Condenser,Evaporator, Fluid Cooler, Gas Cooler,Oil Cooler, Radiator, Refrigeration,Steam to Air Heat Exchanger,superheater etc. |

Features

(1) Excellent anti-wear performance

(2) Less fouling

(3) Compact space

(4) Welded Joints less

The Accessory

Application

In boilers, economizers are heat exchange devices that heat fluids, usually water, up to but not normally beyond the boiling point of that fluid. Economizers are so named because they can make use of the enthalpy in fluid streams that are hot, but not hot enough to be used in a boiler, thereby recovering more useful enthalpy and improving the boiler's efficiency. They are a device fitted to a boiler which saves energy by using the exhaust gases from the boiler to preheat the cold water used to fill it (the feed water).

Related products

Our Company

Shandong Hengtao Energy Saving & Environment Protection Co., Ltd. established in 2003, which is specialized in designing, manufacturing, engineering, supplying of boilers, boiler components and boiler auxiliaries.

Our main products including CFB boiler, coal fired boiler and boiler parts such as tubular air pre-heater, rotary air pre-heater, super heater, re-heater, header, membrane water wall and economizer. We are also the provider for boiler integrated energy-saving solutions and we have EPC qualification.

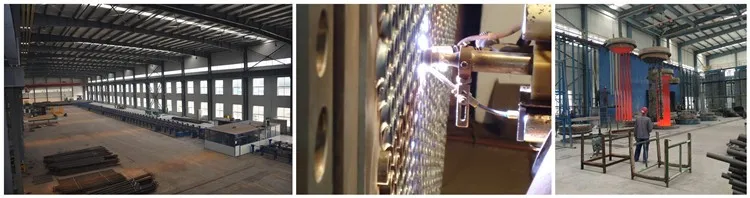

Workshop & Packing & Shipment

Clients

Hengtao products have been exported to Mongolia, Turkey, Thailand, Vietnam, Indonesia, India, Iran and other oversea countries and areas.

Certifications

Grade A boiler manufacturing; installation and contract of electromechanical equipment; EPC qualification for electric power engineering construction; installation, transformation and maintenance qualification of Grade 1 boiler and A2 pressure vessel manufacturing. We also have ISO, TUV, ASME, SGS ect. certifications.

FAQ

Q:Who are you? Trade Company or manufacturer?

A: We are manufacturer and we have our own trade company.

Q: What's your Payment Terms ?

A: L/C( high bank charge, not suggest , but acceptable )

T/T( 70% deposit , 30% before shippment)

100% Western Union in advance. (specially forairshipment or small amount)

Q: What's the Min order to your company?