Brand Name: HANSEN

Model Number: WNS3-1.25-Y(Q)

Place of Origin: Henan, China

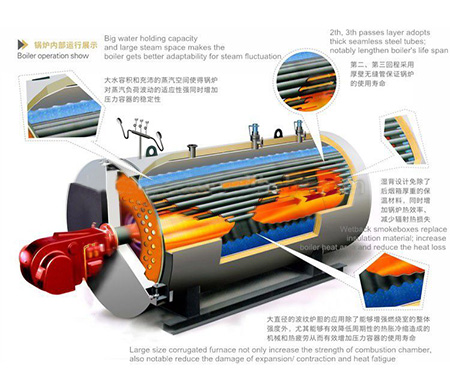

Products Features

a. Energy Saving Italy Burner

Adopting high quliaty low nitrogen split-type burner; pre-heat the air for burner, raise the furnace's temperature and increase combustion efficiency.

b. High Thermal Efficiency more than 95%

Full wet-back and three passes design; adopting spirally corrugated fire tubes to increase boiler heating surface. Additional, it equiped with condensing economizer to full using the latent heat of waste smoke. Boiler's working efficiency can reach more than 95%.

c. PLC Control for Automatic Operation

Advanced PLC full automatic controller gets touch screen and digital computer; automatically regulate water feeding rate, automatically regulate boiler's working pressure, full-auto fault detection/alarm/protection.

d. Convenient Installation/ Maintenance

Compact structure and openable front/back smoke boxes, manhole, handhole, platform ladder. Above designs are convenient for installation, maintenance.

Parameter & Models

The Photo of Commercial Use 3000KG/HR PLC Control LNG LPG Fired Boiler with Exhaust Gas Condenser

|

Product Model |

WNS0.5-0.7-Y(Q) |

WNS0.7-0.7-Y(Q) |

WNS1-0.7-Y(Q) |

WNS1-1.0- Y(Q) |

WNS1.5-1.0-Y(Q) |

WNS2-1.0-Y(Q) |

|

Evaporation (Kg/hr) |

500 |

700 |

1000 |

1000 |

1500 |

2000 |

|

Pressure (Bar/ Mpa) |

7/ 0.7 |

7/ 0.7 |

7/ 0.7 |

10/ 1.0 |

10/ 1.0 |

10/ 1.0 |

|

Steam Temp (℃) |

170 |

170 |

170 |

184 |

184 |

184 |

|

Dimension (m) |

2.9*1.4*1.75 |

2.9*1.5*1.85 |

3.3*1.76*2.1 |

3.3*1.76*2.15 |

3.4*2.1*2.25 |

3.8*2.0*2.2 |

|

Weight (KG) |

3500 |

4150 |

4800 |

5300 |

5900 |

6800 |

|

Loading |

1*20'GP |

1*20'GP |

1*20'GP |

1*20'GP |

1*20'OT/ 40'HQ |

1*20'OT/ 40'HQ |

|

Fuel Consumption (Per Hour) |

Natural Gas

36.7NM3 |

Natural Gas 51.5NM3 |

Natural Gas 73.4NM3 |

Natural Gas 73.4NM3 |

Natural Gas 110.2NM3 |

Natural Gas 146.8NM3 |

|

LPG 28.7KG |

LPG 40.2L |

LPG 57.4KG |

LPG 57.4KK |

LPG 86.1KG |

LPG 114.8KG |

|

|

Diesel 34.4L |

Diesel 55.1L |

Diesel 68.8L |

Diesel 68.8L |

Diesel 103.2L |

Diesel 137.6L |

|

|

Alcohol 58L |

Alcohol |

Alcohol 116L |

Alcohol 116L |

Alcohol 174L |

Alcohol 232L |

|

Product Model |

WNS2-1.25-Y(Q) |

WNS2-1.6-Y(Q) |

WNS3-1.25-Y(Q) |

WNS4-1.25-Y(Q) |

WNS4-1.6-Y(Q) |

WNS6-1.25-Y(Q) |

|

Evaporation (Kg/hr) |

2000 |

2000 |

3000 |

4000 |

4000 |

6000 |

|

Pressure (Bar/ Mpa) |

12.5/ 1.25 |

16/ 1.6 |

12.5/ 1.25 |

12.5/ 1.25 |

16/ 1.6 |

12.5/ 1.25 |

|

Steam Temp (℃) |

194 |

204 |

194 |

194 |

204 |

194 |

|

Dimension (m) |

3.8*2.0*2.35 |

3.8*2.15*2.4 |

4.3*2.1*2.55 |

4.58*2.3*2.65 |

4.58*2.4*2.75 |

5.3*2.4*2.7 |

|

Weight (KG) |

7200 |

7920 |

9100 |

12300 |

13100 |

16200 |

|

Loading |

1*20'OT/ 40'HQ |

1*20'OT/ 40'HQ |

1*40'HQ |

1*40'HQ |

1*20'OT & 20'GP |

1*20'OT & 20'GP |

|

Fuel Consumption (Per Hour) |

Natural Gas 146.8NM3 |

Natural Gas 146.8NM3 |

Natural Gas 220.2NM3 |

Natural Gas 293.6NM3 |

Natural Gas 293.6NM3 |

Natural Gas

440.4NM3 |

|

LPG 114.8KG |

LPG 114.8KG |

LPG 172.2KG |

LPG 229.6KG |

LPG 229.6KG |

LPG 344.4KG |

|

|

Diesel 137.6L |

Diesel 137.6L |

Diesel 206.4L |

Diesel 275.2L |

Diesel 275.2L |

Diesel 275.2L |

|

|

Alcohol 232L |

Alcohol 232L |

Alcohol 348L |

Alcohol 464L |

Alcohol 464L |

Alcohol 696L |

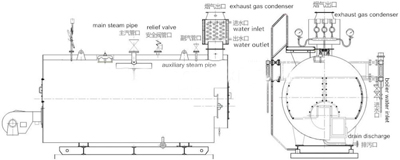

Schematic Diagram

Finished Boiler Body

Finished Products of Commercial Use 3000KG/HR PLC Control LNG LPG Fired Boiler with Exhaust Gas Condenser

Key Auxilliaries

Original Italy RIELLO burner for Commercial Use 3000KG/HR PLC Control LNG LPG Fired Boiler with Exhaust Gas Condenser

Full combustion with low nitrogen

Split-type burner with air pre-heat system

autoignition for start/off

Multistage pump (China famous brand CNP) for Commercial Use 3000KG/HR PLC Control LNG LPG Fired Boiler with Exhaust Gas Condenser

vertical type takes small floor space

stainless steel multistage design

low working noise

high pressure

Re-use the latent heat in exhaust gas to heat the soften water, increase 10% thermal efficiency, save 10% fuel cost.

Re-use the condensate water in exhaust gas; avoid water waste. Dissolve the CO2, NOX, SO2, reduce harmful gas emission; protect the environment.

PLC Control Cabinet for Commercial Use 3000KG/HR PLC Control LNG LPG Fired Boiler with Exhaust Gas Condenser

One button on/off

SIEMENS electronic components

Liquid crystal display (LCD) for entire system

Full automatic regulate the steam pressure, burner and pump

Full-auto fault detection, fault alarm, and chain protection

Full-auto Water Softener for Commercial Use 3000KG/HR PLC Control LNG LPG Fired Boiler with Exhaust Gas Condenser

Ful-auto electronic control operation

High working efficiency 98%

Continuous water output or intermittent water output

Boiler Application

Package & Shipment

Factory & Service

Clean and standard workshops, provides comfortable working environment than traditional companies. We have cleaning department, production supervision department, materials & new boiler storage department.

Our company equiped with automatic cutting machine, automatic bending machine, automatic welding, drilling machine, X-ray Inspection, hydraulic test. Guarantee the quality production in every procedures.

Professional pre-sales/ after-sales make sure your purchase goes smoothly; and help you solve any problem in the futher usage.

In the finished products area, our company display some new finished products. The customer could come for visit, check and order.

WNS20-1.25-Y(Q) Commercial Use 3000KG/HR PLC Control LNG LPG Fired Boiler with Exhaust Gas Condenser

WNS2-1.0-Y(Q), WNS0.5-1.0-Y(Q)

Commercial Use 2000KG/HR PLC Control LNG LPG Fired Boiler

WNS6-1.25-Y(Q) Commercial Use 6000KG/HR PLC Control LNG LPG Fired Boiler with Exhaust Gas Condenser

WNS1-1.0-Y(Q) Commercial Use 1000KG/HR PLC Control LNG LPG Fired Boiler with Exhaust Gas Condenser

WNS1.5-1.0-Y(Q) Commercial Use 1500KG/HR PLC Control LNG LPG Fired Boiler with Exhaust Gas Condenser

WNS4-1.25-Y(Q) Commercial Use 4000KG/HR PLC Control LNG LPG Fired Boiler with Exhaust Gas Condenser

1, Free exchange within 24 Months for non-man-made damaged steam boiler's main-body; and within 12months for non-man-made damaged auxiliaries.

2, Long life technical service.