Shanghai Accessen Group Co., Ltd is a heat exchanger designer, manufacturer, distributor and service in China. Founded in 2002 in Shanghai, we are a Sino-American joint venture company with over 600 employees, 4 manufacturing plants, 400 service outlets covering 27 Chinese provinces, and two technical training and product centers. All of our equipments are certified by America's ASME, America's API, EU's CE, and French's BV. We also meet with ISO quality certificate ISO9001: 2000, ISO environmental quality certificate ISO14001: 2004 and occupational health and safety certificate OHSAS18001: 1999.

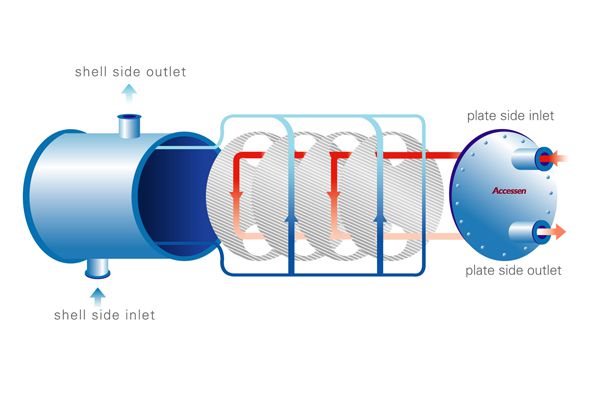

We possess 17 years' experience of producing, selling and serving. We can produce about 3000 pieces assorted plate heat exchanger sets, 20,000 pieces different types PHEs per year. Our company offers a variety of heat exchanger products, such as such as plate heat exchanger, spiral heat exchanger, plate and shell heat exchanger, plate evaporator, plate condenser, and plate heat exchanger system. It is widely used in the HVAC, cooling, power, metallurgy, chemical, food, electronics, marine, and environmental industries.

Our products have been exported to Asia, the Middle East, and Eastern Europe, such as Russia, Ukraine, Poland, Indonesia, Thailand, UAE, Qatar, Saudi Arabia, Pakistan, Bangladesh, Mongolia, India, Iran, Jordan, Venezuela, Macedonia, Singapore and Vietnam. We have designed, produced, and installed heat exchangers for Coca Cola, Sinopec, Siemens, Foxconn, Bayer, and many other Fortune 500 companies and large facilities. We can also provide OEM service.

Being located in Shanghai, the biggest port city of China, we have a transportation advantage. And thanks to this, customers' cost could be greatly reduced.

Quality Control

In order to produce high quality tool with high strength, safety and reliability, we control the quality under the requirements of NDT

The Basic process is

1. Light box inspection

2. Visual inspection for 22 check points

3. PT, UT and RT Inspection

4. Water Hydraulic Pressure Test

Research and Development (R & D)

Accessen Group has two research and development centers, respectively in Shanghai and Beijing, a strong R & D support team in USA. Accessen International USA is an independent consulting firm specializing in Heat Transfer technologies. The company's expertise stems from a team of industry and academic experts with a wealth of experience in the many facets of heat exchangers.

Pre-sale Service

Thermal Transfer Calculation, Thermal Stress Calculation, Plate Heat Exchanger Selection, System Solution Providing .For Plate heat exchanger, we could provide Stainless Steel Plate and Gasket sample to your inspection and the cost of courier is covered by us.

On-sale services

We provide a sum of fragile spare parts with consignment; also include special tools on free basis. The delivery is different subject to order quantities, generally 20 days for regular order.

Warranty and Guarantee

1. Performance guarantee (thermal and pressure drops) is applied to the design as stated in the ACCESSEN data sheet and mechanical for defects due to faulty materials or workmanship are offered for all items of equipment selected and procured by Accessen.

2. The warranty shall be valid for a period of Eighteen (18) moths from the date of delivery, or Twelve (12) months from the date of plant acceptance, whichever date is earlier.

Other Services

Each enquiry and order will be customized design, selection and fabrication. We can conduct factory and onsite training in option Custom sizes are always available.