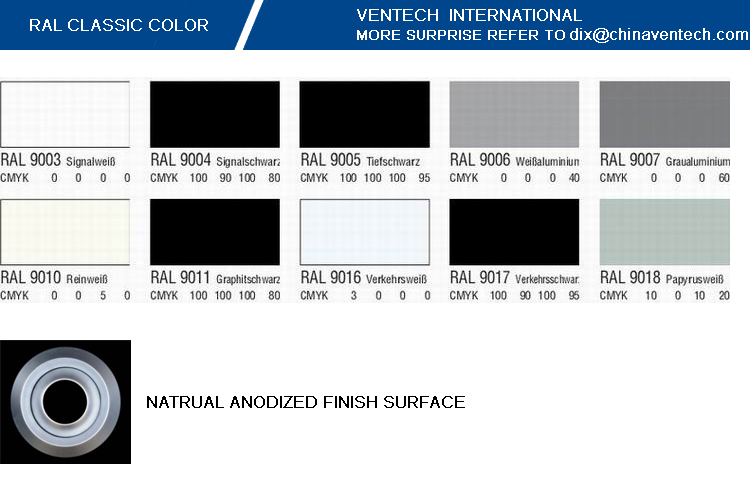

Brand Name: VENTECH

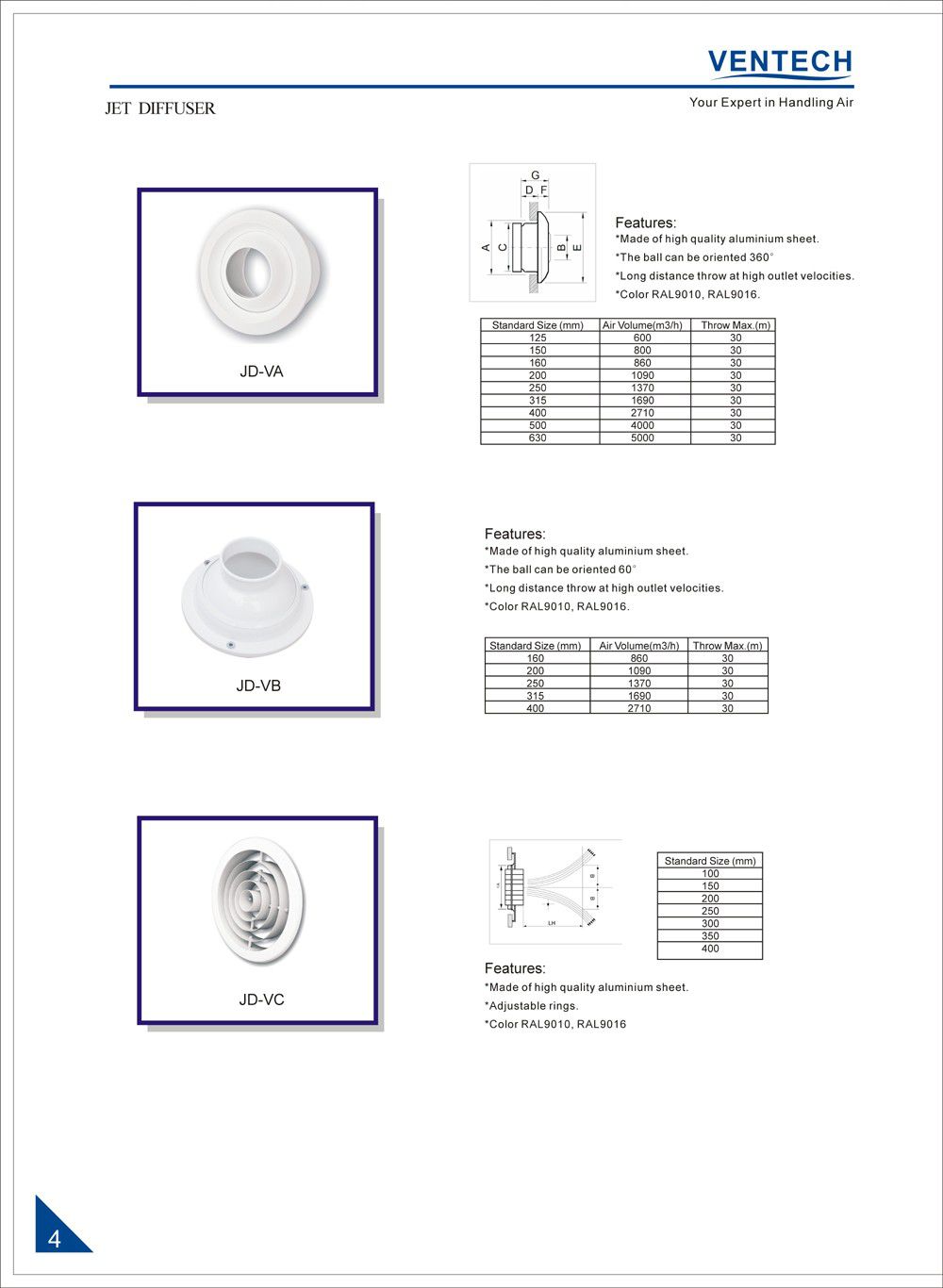

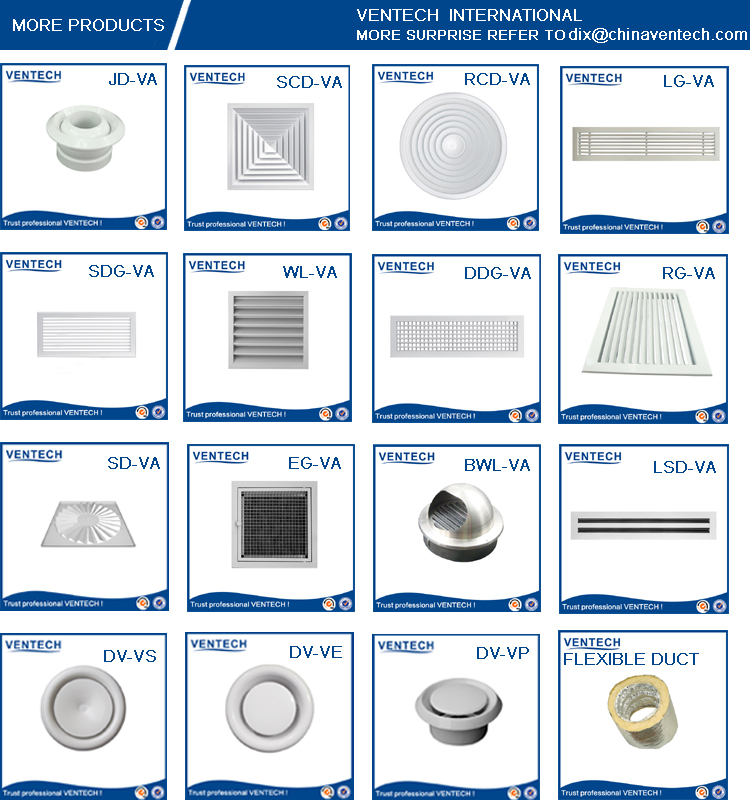

Model Number: JD-VA, JD-VB, JD-VC, JD-VE, JD-VF

Place of Origin: CHINA

VENTECH, YOUR EXPECT FOR AIR DIFFUSER AND GRILLE

Smooth, quite, comfortable. Existing, but feel like nothing.

Ventech Ventilation diffuser is a device that is designed to provide air flow in a room thoroughly.

It works to increase the efficiency of air conditioning units by distributing cooling air. When an even airflow is maintained, drafts and hotspots in a room are eliminated. Providing greater comfort.

Ventech Ventilation diffuser is a device that is designed to provide air flow in a room thoroughly.

It works to increase the efficiency of air conditioning units by distributing cooling air. When an even airflow is maintained, drafts and hotspots in a room are eliminated. Providing greater comfort.

Jet nozzles are used for preference where the supply air from the diffuser has to travel a large distance to the occupied zone. This is the case in large rooms (halls, assembly rooms etc.), particularly when the distribution of air via ceiling diffusers is not possible or not practical. Here jet diffusers are arranged in the side wall areas.

The direction of the air stream from the jet nozzle can be easily adjusted manually to suit particular on site conditions.

The wide range of designs available, the flexibility in adapting to local conditions and compliance with low noise requirements mean that VENTECH jet nozzles can be used in almost any air conditioning system.

Type JD-VA ball jet nozzle inconspicuous and discharges air long distances to the occupied zone. They can be adjusted manually and work heating cooling modes.

JD-VB

Similar aluminum jet nozzle

JD-VE ring jet nozzle is popular in Saudi Arabia market.

JD-VF ring jet nozzle is popular in Isreal market.

JD-VG drump diffuser

What is an aluminum jet nozzle supply air diffuser?

Standard sizes as below:

· Sizes: JD-VG is customized-szes, other models are standard sizes as below:

· Ball jet nozzle neck size:100, 125, 150, 160, 200, 250, 315, 400, 500, 630

Ring jet nozzle neck size:100, 150, 200, 250, 300, 350, 400

How to make an aluminum jet nozzle supply diffuser?

In order to make a high quality jet nozzle, Ventech people introduce a whole production line with advanced swirl pressing are operated by experienced workers.

Firstly, our workers swirl press the aluminum sheet, then comes to the installation line.

Before polishing, the jet diffuser should be washed for 10mins then baked for 30mins. Power coated is arranged behind the polishing step, by using totally-closed powder finishing line and parching space, the perfect diffuser rolls off the products line and ready to be packed, QC is the priority during each step of the mass productions. We have professional QC to check quality before products go to next step.

· pack in carton, pallect, container.

· 1pcs/ctn

hdrum aluminum jet supply air diffuser

drum aluminum jet supply air diffuser

drum aluminum jet supply air diffuser

drum aluminum jet supply air diffuser

drum aluminum jet supply air diffuser