Brand Name: Peide

Model Number: FQG

Place of Origin: China

Industrial shallow layer medium quartz sand filter

Quartz sand filter Instruction of Shallow Medium Filter

Shallow Medium Filter (also with name of FQG system) is a kind of high efficiency filter equipment in cutting down water turbidity, and purifying water. It uses silica sand asits filter medium. Under a certain pressure, the muddy water come through the granular or nongranular silica sand, which can efficiently hold back suspended solids, organisms, colloidal solids, micro-lives, chlorine, odour and heavy metal ions, etc.

It consists of several standard filter tank unit, with unique water distributor and water collector inside.automatic backwash valve can control all system’s backwash process.

Quartz sand filter Application

Shallow Medium Filter is mainly used in pretreatment in water turbidity removal, water softening, electrodialysis, electrodialysis reversal.

However, it makes function on surface water, under ground water as well. Shallow Medium Filter can also be widely used in fields of electronic power, petrochemical,metallurgy,electroplating, papermaking, textile, pharmacy, soft drinks, living water, industrial water, swimming pool, etc.

Quartz sand filter Features

Shallow media filter can widely used at different application, such as water filtering, cooling water by-pass filtering, waster water treating, etc.

1. Shallow media filter has flexible modules, which can combined under actual flow rate, on-site area.

It is operated backwash automatically, with time control, differential pressure control. Each filter element start backwash one by one, while no need stop operation in backwash.

2. With smooth water allocation. High efficiency in backwash, water saving, only 30% water consumption of traditional one. Filter uses ASM filter media, which is easy wash.

3. With unique 48” ball filtering unit, and light weight for the whole system. The normal concrete base can used to place. Easy install, no need any boom equipment.

4. With good anti-corrosion feature.

5. With lost cost, but long lifetime.

6. Water quality:

inlet water turbidity <80mg/L, outlet quality reach <20mg/L

inlet water turbidity <20mg/L, outlet quality reach <5mg/L

7. Flow rate: it can treat 30-500m³/h

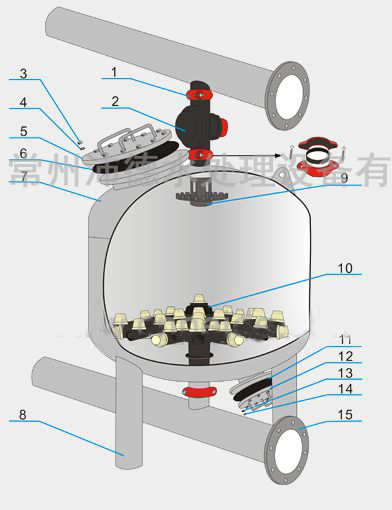

Quartz sand filter Internal Structure

Filter structure: main part includes filter tank, water distributor, water collector, hand hole and support base, etc.

Filter tank: it gives enough space for water distributor and collector. Each water collector has 55 water caps, which reforms a internal recycle flow when backwash, no sand leak.

Water distributor: it makes sure water flow smoothly on the padding sand media.

water collector: with 55 unique mushroom shape water caps makes sure water pressure in a balance. It can reforms a internal recycle flow when back wash, no sand leak.

Hand hole: There have a up and down hand holes, which is easy for installing and replacing water distributor and collector. Meanwhile, the upper hand hole, which is easy for inspecting and adding silica.And down hand hole, which is easy for clear and repair.

Support base: it is assemble, it can adjust in according to on-site situation.

|

Model |

Inlet diameter(mm) |

Outlet diameter(mm) |

Picture |

Material |

|

PD-58P |

100 |

100 |

|

Plastic |

Quartz sand filter Silica sand

Silica sand: mined from silica bed. After milling, it becomes into irregular angular shape. When mixed with concrete, it has a good adhesion, which can increase slurry strength.

Sea silica: with smooth outside, and even grind and with salty.

|

| Silica sand |

Quartz sand filter Operation

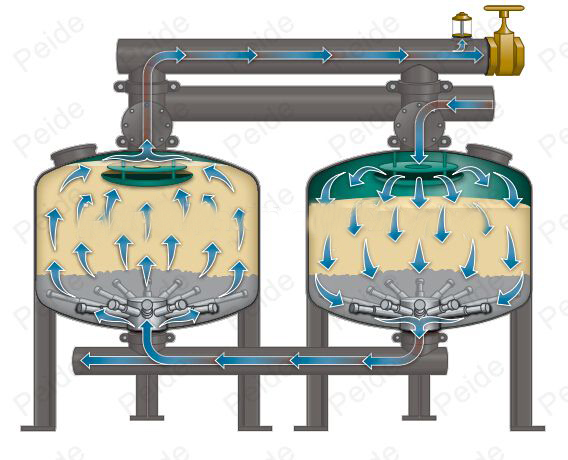

Filtration Process

- The contaminated water enters the tank through the inlet manifold, transitioning to the 3-way valve and into the top inlet of each tank

- The two-stage deflector creates a uniform distribution for laminar flow across the media bed while avoiding channeling of the media bed

- Particulate is trapped and retained within the media bed resulting in clean process water flowing out through the stainless steel wedge wire underdrain, to the outlet of each filter tank and to the outlet manifold for end use

Backwash Process

- Backwash sequence is initiated by either elapsed time of the controller or pressure differential between the inlet and outlet manifolds

- Water or air pressure opens the 3-way valve causing the reverse flow of a portion of filtered water up through the stainless steel underdrain to hydraulically and uniformly lift the media bed

- The use of a hydraulically balanced underdrain in conjunction with a gravel pack creates a proper and uniform lift of the media bed while avoiding a turbulent backwash

- Entrapped particulates are released during the backwash event, exhausted through the backwash manifold and routed to a convenient location

- One tank at a time is backwashed while continuing to process water for use until the entire system is clean

- Once completed with the backwash, filtration continues until the next backwash event.

Quartz sand filter Control manner

Peide Backwash control valve is started by water pressure or an external power source.

Peide backwash control valve is composed of solenoid valve, hydraulic relay valve actuator or three-way valve.

Peide filter backwash control valve outlet normally open, drain valve normally closed.

Each outlet is sealed by its own independent sealing seat, but they are controlled by the same stem of seal diaphragm.

Valve is a complete, interactive set. When one outlet is turned on, the other outlet is in a closed state,

So backwash valve can be operated in two modes:

Technical and performance Parameters

|

Model |

FQG48-1 |

FQG48-2 |

FQG48-3 |

FQG48-4 |

FQG48-5 |

FQG48-6 |

|

Inlet & outlet Diameter(mm) |

100 |

200 |

200 |

200 |

200 |

200 |

|

Drainage(mm) |

80 |

100 |

100 |

100 |

100 |

100 |

|

Flow rate(m3/h) |

15-50 |

30-100 |

45-150 |

60-200 |

75-250 |

90-300 |

|

Maximum pressure(Mpa) |

0.6(1.0) |

0.6(1.0) |

0.6(1.0) |

0.6(1.0) |

0.6(1.0) |

0.6(1.0) |

|

Filter area(m2) |

1.13 |

2.26 |

3.39 |

4.52 |

5.65 |

6.78 |

|

Total length(mm) |

1320 |

2640 |

3960 |

5280 |

6600 |

7920 |

|

Quartz sand(kg) |

860 |

1720 |

2580 |

3440 |

4300 |

5160 |

|

Drain valve interface(inch) |

4”×3” |

4”×3” |

4”×3” |

4”×3” |

4”×3” |

4”×3” |

Filter medium and flow rate

| Filtration precision | Filter material(12-40cm) | Recommend flow rate(m3/h) | Backwash flow rate(m3/h) |

| General filter | Quartz sand 1.0-2.0mm | 40-50 | 35-55 |

| Precious of quartz sand | Quartz sand 0.5-1.0mm botton1.0-2.0mm |

15-25 | 25-40 |

Other diameter silica sand can also be used, which reaches into function of filter precision and stain resistance.

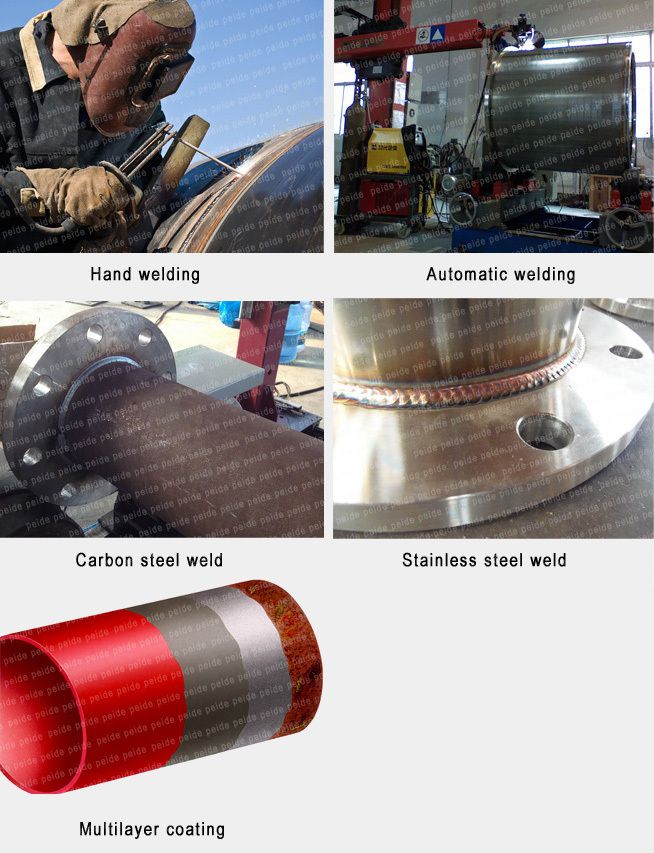

Manufacturing material

| Filter chamber | Carbon steel(Epoxy asphalt coating paint) |

| Filter medium | Delicate natural quartz sand |

| Water distributor | Engineering plastics |

| Water collector | Engineering plastics |

| Sealing ring | Nitrile rubber |

Installation

1. Check evenness of floor: it requires floor even, each meter evenness should less than 10mm, the concrete floor can bear 3 ton/m2.

2. Line tanks units in a queue in according to drawing.

3. Install drain valve.

4. Install general in/outlet pipeline. Notice to protect plastic drain valve from damaging.

5. Install differential pressure switch, in/outlet pressure gauge and vent valve.

6. Wire for the whole filter and pipelines.

Step1. Installation details

Step1. Installation details

1.clamp

2.2way-3positon valve

3.six angle bolt

4.metal gasket

5.up and down hand hole

6.rubber gasket

7.filter tank

8.support legs

9.water distributor

10.water collector

11.rubber gasket

12.down hand hole cover

13.mental gasket

14.six angle bolt

15.inlet and outlet

1 Water distributor installation

16.O-ring N122*7

17.water distribution frame

18.water distribution plate

19.water distribution cover

1.Place water distribution palte (18) on plate, (17),tighten cover, and fix with o-ring(16).

2.Install water distributor from up hand hole. Insert water distribution frame into flange, tighten inlet screw cover, fix it at flange too.

2 Water collector installation

20.pressure cap

21.water cap

22.screw cap(23),connecting joint(24).water disperse 25.collector(26).O-ring N122*727.upper water collecting pipe

25.collector(26).O-ring N122*727.upper water collecting pipe

28.upper water collecting pipe cover

29.down water collecting pipe

1. Fix upper water collecting pipe cover (28) and three water caps (21) into pipelines (27), fix these three water capsat down water collecting pipe (29). Make sure each water collector needs 9 sets collecting upper and down pipelines.

2. Place two water allocate (24) at collecting tank (25). Fix a water cap at pressure cover (22), and tighten the pressure cover at collecting tank (25). Fix water allocating well, again fix a O-ring (26). Then place up and down , ecting pipes inside the tank from down hand, phole. Joint with flange at tank bottom, tighten with screw cap (9). Remember to inspect collecting tank move or not.

3. Joint each collecting pipe into holes. Two man install cooperate, insert a joint fitting (23) to fix all collecting pipes.

And unscrew water , screw cap (9), and fix with round flange.

3 Supper hand hole cap installation

Put o-ring into o-shape socket, cover with hand hole flange (4). Tighten with screw bolt (2) include gasket(3).

4 Support base installation

Supply support legs(3) and support leg covers (10).

Step 2:QLQ system installation

QLQ shallow media filtering system

1. in/outlet DN200

2. filter tanks

3. cam lock joint fitting

4. vent valve 1"

5. in/outlet pressure gauge

6. inlet pressure gauge

7. inlet pipe DN200

8. three way drain valve 4"*3"

9. drain pipe DN100

10.differential pressure switch

Details installation process:

1.Range filter tank in order. Notice to ensure hand hole direction outside, so that easy for add sand and maintenance.

2.Install outlet pipe (1), adjust filter tank (2), to make sure outlet branch pipe and tank’s water collector at a same level. Weld cam locks (3), fix well.

3.Install three way drain valve (8), fix with cam locks.

4.Install inlet pipe (7), adjust inlet branch pipe, to make sure inlet branch pipe and three way drain valve’s inlet in a same level, welding with cam lock(3). Fix well.

5.Install drain pipe (9). Keep drain , branch, pipe and three way drain valve at a line, welding with cam lock. Fix well.

Install differential pressure switch (10), inlet and outlet water pressure gauge (5) and (6), vent valve (4).

Step 3:QLQ system pipeline and wire install

QLQ pipeline and wire drawing

1. Hydraulic pipeline connection

1.Each three matched with one solenoid. Current pipeline as a,b,c,d,e,f as shown.

2.Differential pressure (high pressure connection) match with inlet water pipe, low pressure connect with outlet pipe .

See dot line g1, g2 shown.

2. wire connecting

1. Each solenoid has two terminal connector. E.g: 1# solenoid fire wire connect at 1, null wire at N.

2. Differential pressure switch, power supply wire (AC220), earth wire connecting way please see check drawing.

Equipment more pictures