Brand Name: Alfa laval

Model Number: M20

Place of Origin: China

Plate heat exchanger is a kind of new high-efficiency heat exchanger made by a series of metal sheet with a corrugated shape,the heat is exchanged through the platse. Plate heat exchanger is an ideal heat exchange equipment for liquid - liquid, liquid - vapor. It has the characteristics of high heat transfer efficiency, small heat loss, compact and light structure, small occupation area, convenient installation and cleaning, wide application and long service life. Under the same pressure loss, the heat transfer coefficient is 3-5 times higher than that of the tubular heat exchanger, and the area of the heat transfer coefficient is 1/3, and the heat recovery rate can be as high as 90%.

Working principle

Channels are formed between the plates and the corner ports are arranged so that the two media flow through alternate channels. The heat is transferred through the plate between the channels, and complete counter-current flow is created for highest possible efficiency. The corrugation of the plates provides the passage between the plates, supports each plate against the adjacent one and enhances the turbulence, resulting in efficient heat transfer.

Plate Heat Exchanger Gasket Model

|

plate material |

Stainless steel(SUS304、316L etc )、Titanium and Nickle |

|

gasket material |

NBR:(applicable temperature -15-+120℃) |

|

Thickness of plate |

0.5mm |

|

Features |

Cost effective and lower operation cost |

|

Compact structure, |

Thin plate |

|

Less weight |

Only 20-30% weight of shell-tube heat exchanger |

|

Less water consumption |

High thermal efficiency allows BPHE only 1/3 |

|

Durable |

Up to200°C temperature and 45 bar pressure |

|

Minimal Fouling |

The greatest turbulence in the flow |

|

High Quality |

Jiangxing is recognized as the best heat exchanger producer in domestic market with years of operation experience and accurate computer aided design. |

Application

Food industry

Milk pasteurization, Milk and beverage pasteurization, Wine tempering, Bottled water treatment, CIP (Cleaning-in-Place) heating, Reverse osmosis water.

Marine application

Central cooling of the main or auxiliary engines or turbines, Lubrication oil cooling, Recooling of circulated water for cooling cylinders, pistons, injection nozzles, Cooling of Baoder oil, compressor oil and other lubricants, Preheating of lubrication oil and heavy fuel oil, Preheating of seawater for fresh water production, Heat recovery, Heat exchange to air-condition the passengers' cabins and freight spaces

Others

Turbine oil cooler, Chemical industry, district heating, district cooling, swimming pool heating, solar heating,

High quality

Reasonable price

Packing

Plywood Case

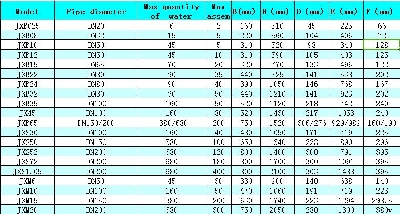

We provide all the following models: