Alfa Laval has become a part of the Honeywell Connected Plant partner ecosystem, contributing to a solution that optimizes the performance of plants and process equipment in the process industries, including refining and petrochemicals.

Alfa Laval Packinox heat exchangers have for many years been specified by Honeywell UOP as a mandatory component in the production processes for making high octane fuels and aromatics. The two companies are now extending their collaboration, combining their respective expertise within Honeywell’s Connected Plant program.

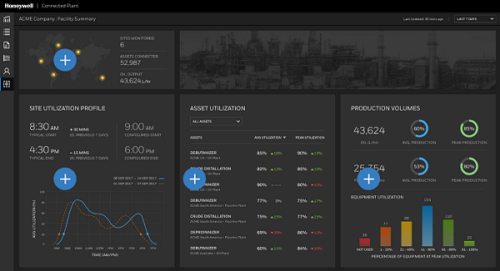

Honeywell’s cloud-based software solution, used in refineries and petrochemical plants, continually collects and analyses data from process units so plant owners can optimize their operations. Being a part of the Connected Plant Program, Alfa Laval will use this data to further improve the Packinox operating recommendations that it provides to its customers as well as enable further innovation for its products.

“We are very proud to be part of the Honeywell program which will drive customer value – to further optimize our customers processes and maximize their energy efficiency, uptime and profitability,” says Susanne Pahlén Åklundh, President of the Energy Division. “With information from the program we, together with Honeywell UOP and our customers, will define additional process improvements.