Brand Name: Henan yuanda boiler

Model Number: DZH

Place of Origin: Henan, China (Mainland)

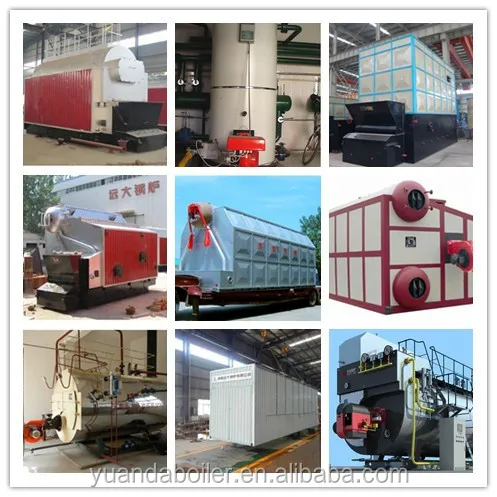

Wood-fired steam boiler for cement factory,cement factory boiler

Some pictures first :

Manual boiler technical data:

| Manual boiler model | DZH1-1.0 | DZH2-1.25 | DZH4-1.25 | DZH4-1.6 |

| Steam evaporation(t/h) | 1 | 2 | 4 | 4 |

| Working pressure(Mpa) | 1.0 | 1.25 | 1.25 | 1.6 |

| Feeding water temp(°c) | 20 | 20 | 20 | 20 |

| Steam temp(°c) | 184 | 194 | 194 | 204 |

| Hydraulic test(Mpa) | 1.4 | 1.65 | 2.0 | 2.0 |

| Water capacity(m3) | 3.15 | 4.75 | 7.7 | 7.7 |

| Radiation heating area(m²) | 4.8 | 6.34 | 11.81 | 11.81 |

| Smoke blackness(Ringelman ) | ‹1 | |||

| Fire grate area(m²) | 1.3 | 2.55 | 4.72 | 4.72 |

| Delivery weight(t) | 8.6 | 15 | 18.5 | 19.2 |

Wood-fired steam boiler for cement factory,cement factory boiler--DZH boiler series !

Highly praised by the customers overseas !

High cost performace & 100% stable reliablity !

Advantages:

1. Spirally corrugated tube

function: heat transfer enhancement ,1-2 times heat transfer efficiency than before. reduce the spirally corrugated tube numbers,and improve the suppleness to avoid the tube plate cracking

2. Arched tube plate

function : reduce the thermal stress of weld and improve the tube plate suppleness,meantime, simplify the structure

3.Airfoil flue

Function : reduce the smoke temperature of high temperature tube plate,and then reduce the thermal load of boiler bottom.

4.Smook dust separation chamber

Function : reduce the original dust concentration of the steam boiler, and protect environment.

5.Fire-water tube mixed design

Function: optimum structure design ,reduce the boiler size and can save 1/3 building cost of the boiler room.

Burning fuel--various kinds of wood/biomass :

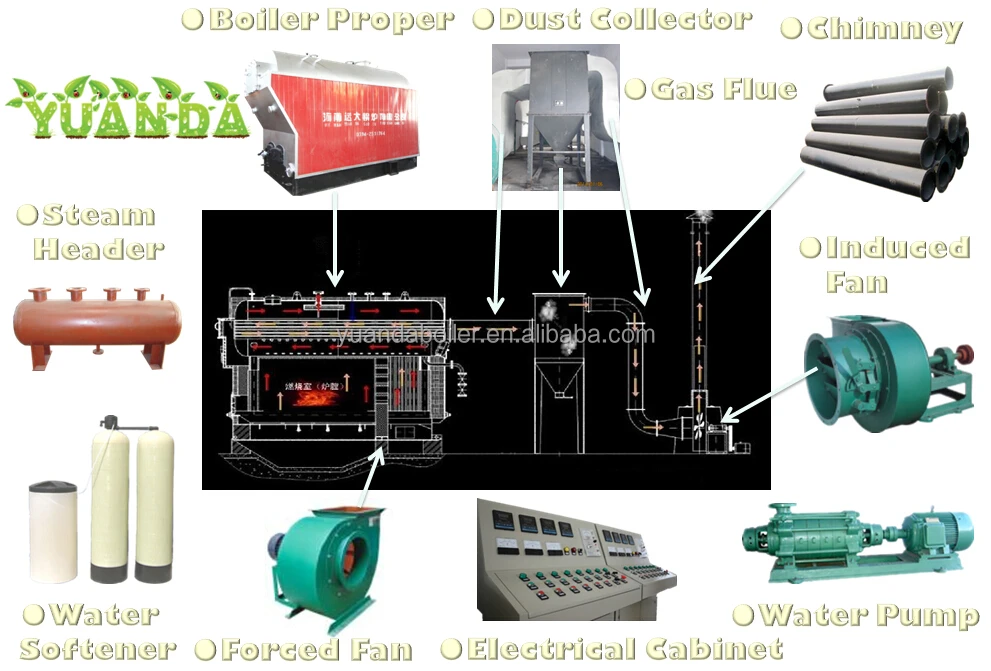

To assure the boiler's high efficiency runnning ,we will confirgure the following auxiliaries /boiler room equipment for our boilers:

Wood /biomass manual steam boiler, highly praised by the customer!

Quality Control

1.58 years corporate reputation.

2.X-ray flaw detection.

3.Higher grade welder certificate.

Guarantee and After-sale service

1.One year warranty and full-life service for all our boilers.

2.A full range of original spare parts are available for all yuanda boilers.

3.24 hours technical support by email.

4.Engineers available to service overseas.

So far, our boiler have been sold to over 20 countries and have been highly praised by customers ! Sincerely welcome the factory visiting !

Quality is life for our factory since found in 1956,during these 58 years and huge international market ,we have been committed to provide the best products to our customers, and created the the following product series:

1.Coal/biomass/gas/oil steam boiler : 0.5-20ton/hr

2.Coal/biomass/wood /gas/oil hot water boiler :0.35-14MW

3.Pressure:0.4-2.5Mpa,4bar-25bar

4.Vertical/horizontal boiler

5. Thermic fluid boiler ,coal/biomass fuel

6.Vacuum boiler:negative pressure running

7. Gas condensing boiler

8. Transportation container boiler room

Yuanda boiler found in 1956, which is the first enterprise that get the boiler manufacturing qualification in China, we have been committed to researching and innovating , and take the leading position in China ,so sincerely welcome !

Quality control/manufacturing scene:

Company qualification:

Contact Us: