Brand Name: YORK

Model Number: YKEP BD BD K7 Q3 - DL - EF B S

Place of Origin: Jiangsu, China (Mainland)

JOHNSON CONTROLS

FORM 160.87-EG1 (916)

2

Approvals

• ASME Boiler and Pressure Vessel Code – Section Vlll Division 1

• AHRI Standard 550/590 or 551/591 (When applicable up to 3,000 tons or 10.500 kW)

• UL 1995 – Heating and Cooling Equipment

• ASHRAE 15 – Safety Code for Mechanical Refrigeration

• ASHRAE Guideline 3 – Reducing Emission of Halogenated Refrigerants in Refrigeration and Air-Conditioning

Equipment and Systems

• N.E.C. – National Electrical Code

• OSHA – Occupational Safety and Health Act

Nomenclature

The YORK® YKEP Chiller extends the range of the YORK single-stage centrifugal chiller

product range by providing additional capacity and greater efficiency through an economized

cycle. This is the only product available that uses a second single-stage compressor

to perform half lift in parallel. The advantage of this cycle is greater control flexibility to

move the intermediate pressure to maximize efficiency or extend cooling capacity.

MATCHED COMPONENTS MAXIMIZE EFFICIENCY

Actual chiller efficiency cannot be determined by analyzing the theoretical efficiency of

any one chiller component. It requires a specific combination of heat exchanger, compressor,

and motor performance to achieve the lowest system kW/ton. YORK YKEP chiller

technology matches chiller system components to provide maximum chiller efficiency under

actual – not just theoretical – operating conditions.

REAL-WORLD ENERGY PERFORMANCE

Johnson Controls pioneered the term “Real-World Energy” to illustrate the energy-saving

potential of focusing on chiller performance during off-design conditions. Off-design is not

only part load, but full load operation as well, with reduced entering condenser water temperatures

(ECWTs). This is where chillers operate 99% of the time, and where operating

costs add up.

YORK YKEP chillers are designed to operate on a continuous basis with cold ECWTs and

full condenser flow at all load points, taking full advantage of Real-World conditions. This

type of operation benefits the cooling tower as well; reducing cycling of the fan motor and

ensuring good coverage of the cooling tower fill.

YORK YKEP chillers offer the most efficient Real-World operation of any chiller, meaning

lower operating costs and an excellent return on your chiller investment.

OPEN-DRIVE DESIGN

Hermetic motor burnout can cause catastrophic damage to a chiller. The entire chiller

must be cleaned, and the refrigerant replaced. YORK YKEP centrifugal chillers eliminate

this risk by utilizing air-cooled motors. Refrigerant never comes in contact with the motor,

preventing contamination of the rest of the chiller. Insurance companies that offer policies

on large air conditioning equipment often consider air-cooled motors a significant advantage

over hermetic refrigerant-cooled units.

HIGH EFFICIENCY HEAT EXCHANGERS

YKEP chiller heat exchangers offer the latest technology in heat transfer surface design to

give you maximum efficiency and compact design. Waterside and refrigerant side design

enhancements minimize both energy consumption and tube fouling.

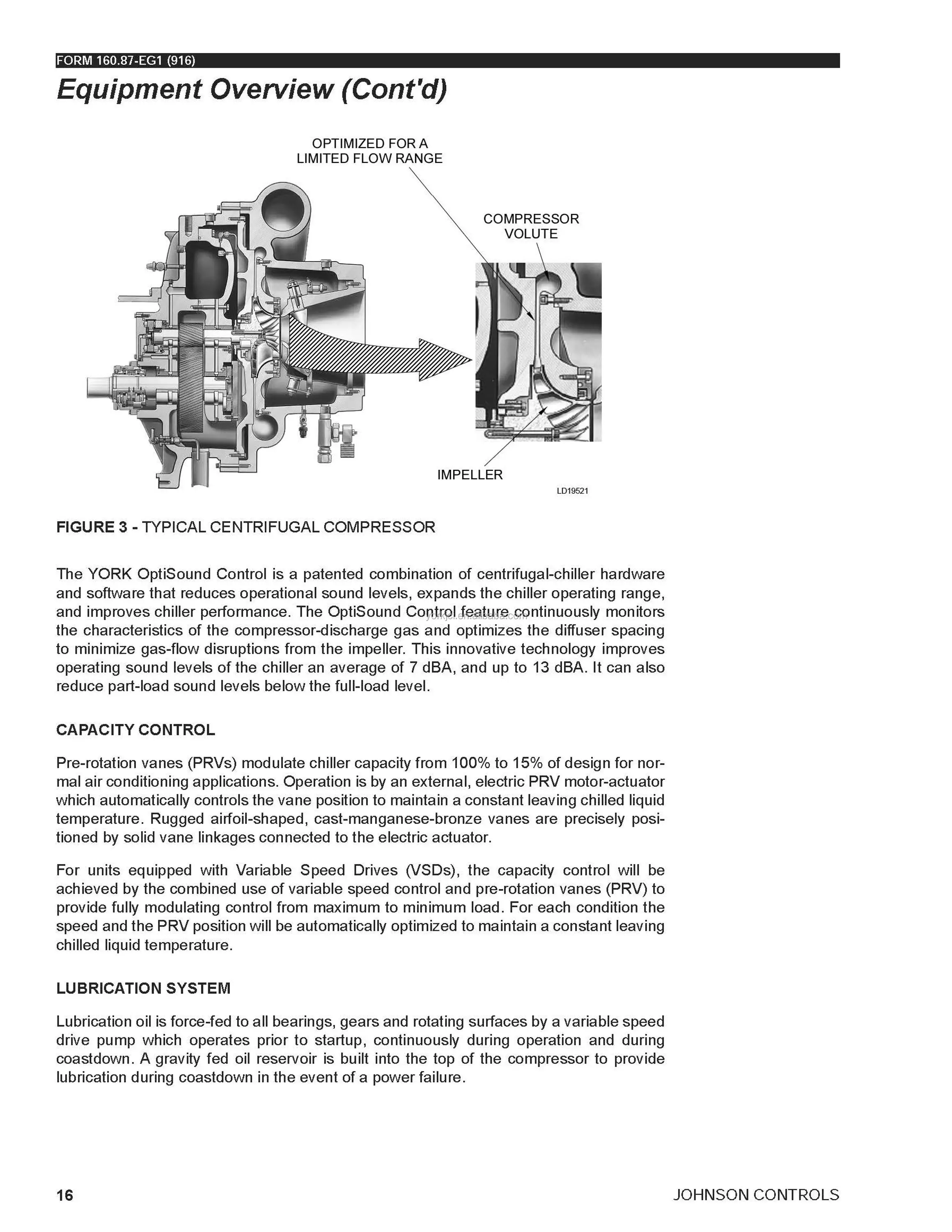

SINGLE-STAGE COMPRESSOR DESIGN AND EFFICIENCY PROVEN IN THE MOST

DEMANDING APPLICATIONS

Designed to be the most reliable chillers we’ve ever made, YORK centrifugal chillers

incorporate a single-stage compressor design. With fewer moving parts and straightforward,

efficient engineering, YORK single-stage compressors have proven durability records

in hospitals, chemical plants, gas processing plants, the U.S. Navy, and in other

applications where minimal downtime is a crucial concern.

In thousands of installations worldwide, YORK single-stage compressors are working to

reduce energy costs. High strength aluminum-alloy compressor impellers feature backward

curved vanes for high efficiency. Airfoil shaped pre-rotation vanes minimize flow disruption

for the most efficient part load performance. Precisely positioned and tightly fitted,

they allow the compressor to unload smoothly from 100% to minimum load for excellent

operation in air conditioning applications.

PRECISION CONTROL OF COMPRESSOR OIL PRESSURE

Utilizing our expertise in variable-speed drive technology and applications, Johnson Controls

has moved beyond the fixed head and bypass approach of oil pressure control.

The old approach only assures oil pressure at the outlet of the pump rather than at the

compressor, and allows no adjustment during chiller operation. The YKEP chillers feature

a variable-speed drive oil pump for each compressor, monitoring and providing the right

amount of oil flow to the compressors on a continuous basis. This design also provides

sophisticated electronic monitoring and protection of the oil pump electrical supply, ensuring

long life and reliable operation of the oil pump motor. Variable-speed drive technology

reduces oil pump power consumption, running only at the speed required, rather than at

full head with a pressure regulating bypass valve.

TAKE ADVANTAGE OF COLDER COOLING TOWER WATER TEMPERATURES

YORK YKEP centrifugal chillers have been designed to take full advantage of colder cooling

tower water temperatures, which are naturally available during most operating hours.

Considerable energy savings are available by letting tower water temperature drop, rather

than artificially holding it above 75°F (23.9°C), especially at low load, as some chillers

require.

OFF DESIGN PERFORMANCE

Since the vast majority of its operating hours are spent at off design conditions, a chiller should

be chosen not only to meet the full load design, but also for its ability to perform efficiently at

lower loads and lower tower water temperatures. It is not uncommon for chillers with the same

full load kW/ton to have an operating cost difference of over 10% due to part load operation.

Part load information can be easily and accurately generated by use of a computer. And because

it is so important to an owner’s operating budget, this information has now been standardized

within the AHRI Certification Program in the form of an Integrated Part Load Value

(IPLV), and Non Standard Part Load Value (NPLV).

The IPLV/NPLV formulas from AHRI Standard 550/590 much more closely track actual chiller

operations. A more detailed analysis must take into account actual building load profiles, and

local weather data. Part load performance data should be obtained for each job using its own

design criteria.

AHRI CERTIFICATION PROGRAM

YORK YKEP chillers have been tested and certified by Air- Conditioning, Heating and Refrigeration

Institute (AHRI) in accordance with the latest edition of AHRI Standard 550/590

(I-P) & 551/591 (up to 3,000 tons or 10.550 kW). Under this certification program, chillers are

regularly tested in strict compliance with this standard. This provides an independent, thirdparty

verification of chiller performance. Refer to the AHRI site at: www.ahrinet.org/water_chill

ing+packages+using+vapor+compressioncycle+_water_cooled_.aspx for complete Program

Scope, Inclusions, and Exclusions as some options listed herein fall outside the scope of the

AHRI certification program. For verification of certification, go to the AHRI Directory at www.

ahridirectory.org.

UL COMPLIANCE – YOUR ASSURANCE OF RELIABILITY

YORK YKEP centrifugal chillers are approved to UL Standard 1995 for listing by a qualified

nationally recognized testing laboratory for the United States and Canada. Recognition

of safety and reliability is your assurance of trouble free performance in day-to-day building

operation. Some chiller options or modifications may affect the UL compliance of the chiller.

Some examples include: special motor enclosures (like TEFC, TEWAC, or TEAAC) or special

panels (NEMA 4X) or special unit wiring options (anything other than NEMA 1). For further

clarification, contact your local Johnson Controls Sales Office.

COMPUTERIZED PERFORMANCE RATINGS

Each chiller is custom matched to meet the individual building load and energy requirements.

Several standard heat exchanger tube bundle sizes and pass arrangements are

available to provide the best possible match.

It is not practical to provide tabulated performance for each combination, as the energy

requirements at both full and part load vary significantly with each heat exchanger and

pass arrangement. Computerized ratings, tailored to specific job requirements, are available

through each Johnson Controls Sales Office.

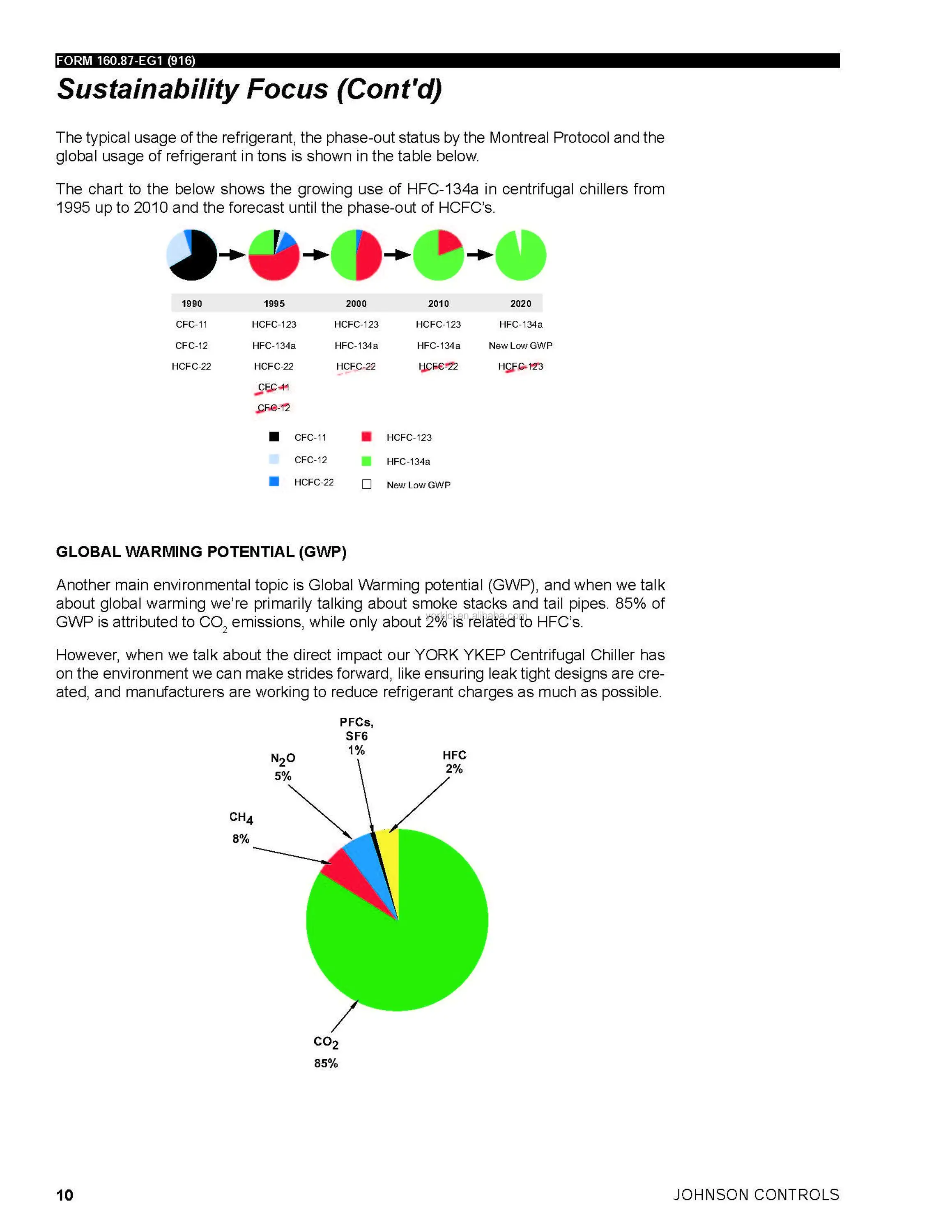

Monitoring stations showed that ozone-depleting chemicals were steadily increasing in

the atmosphere. These trends were linked to growing production and use of chemicals

like chlorofluorocarbons (CFCs) for refrigeration and air conditioning, foam blowing, and

industrial cleaning. Measurements in the laboratory and the atmosphere characterized

the chemical reactions that were involved in ozone destruction. Computer models employing

this information could predict how much ozone depletion was occurring and how

much more could occur in the future.

Observations of the ozone layer showed that depletion was indeed occurring. The most

severe and most surprising ozone loss was discovered to be recurring in springtime over

Antarctica. The loss in this region is commonly called the “ozone hole” because the ozone

depletion is so large and localized. A thinning of the ozone layer also has been observed

over other regions of the globe, such as the Arctic and northern middle latitudes. The work

of many scientists throughout the world has provided a basis for building a broad and

solid scientific understanding of the ozone depletion process. With this understanding,

we know that ozone depletion is occurring and why. And, most importantly, we know that

if ozone-depleting gases were to continue to accumulate in the atmosphere, the result

would be more depletion of the ozone layer. In response to the prospect of increasing

ozone depletion, the governments of the world crafted the 1987 United Nations Montreal

Protocol as a global means to address this global issue. As a result of the broad compliance

with the Protocol and its Amendments and Adjustments and, of great significance,

industry’s development of “ozone friendly” substitutes for the now-controlled chemicals,

the total global accumulation of ozone-depleting gases has slowed and begun to decrease.

This has reduced the risk of further ozone depletion.

THE MONTREAL PROTOCOL ADDRESSED CFC’S AND HCFC’S

The Montreal Protocol (MP) addressed CFC’s and HCFC’s with phase out schedule for

all member parties of the MP based on the ODP characteristics. So this affects the first

two categories of refrigerants listed in the table. Manufacturers in developed nations are in

the final processes of converting from HCFC’s to HFC’s in accordance with the Montreal

Protocol treaty. Markets in developing countries are already seeing a transition away from

HCFC’s ahead of legislative requirements.

HCFC’s were used as a transitional refrigerant as they were a “Lesser Evil” and allowed

the HVAC industry to quickly transition away from CFCs while maintaining energy efficiency.

The fact remains that they destroy the ozone layer and are legislated to be completely

phased out.

The Montreal Protocol does not extend to HFC’s as they have no ODP nor does it extend

to natural refrigerants for the same reason.

Qinhao Zhan

HVAC&R Engineer

Refrigeration and Process Systems

China Refrigeration (York by Johnson Controls)

Mobile:+86 13818154378 18625150627

QQ: 826554493

862417098

Johnson Controls York Industrial Refrigeration - Shanghai Jiusui-Ref Systems Engineering Co., Ltd.: harsh industrial environments breakthrough in industrial refrigeration + accuracy + = large cooling load fluctuations York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd tailor-made industrial refrigeration systems!

Provide personalized solutions for five major areas! Can be mainly used in petroleum, petrochemical process; chemical technology; synthetic rubber technology; fertilizer production process and chemical fiber textile technology. A number of other applications to meet different needs!

In addition to the above five major areas, York- Shanghai Jiusui-Ref Systems Engineering Co., Ltd Industrial refrigeration approved for use in air separation plants, liquefaction plants, carbon dioxide recovery systems, pharmaceutical industry, tobacco industry and steel plants, power plants, electronics factories and other process cooling And refrigeration systems.

York Shanghai Jiusui-Ref Systems Engineering Co., Ltd is located in the petrochemical industry, whether it is upstream natural gas compression, midstream liquefied natural gas storage, transshipment, or downstream air separation, liquefaction unit, as long as the compression-related York- Shanghai Jiusui-Ref Systems Engineering Co., Ltd are involved!

Advanced control system + energy efficient refrigeration equipment + overall solution = York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd a full range of food refrigeration business!

Food processing + large cold storage + poultry slaughter + beer drinks + dairy products + aquatic fisheries + small logistics distribution center, etc. = York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd food refrigeration business coverage!

P.K. "China cold village" -58 ℃ low temperature! (-28 ℃ ~ 15 ℃), and even tuna low-temperature cold storage (-55 ℃ ~ -60 ℃), York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd food refrigeration business can be, but also the production of cold storage, Complete turnkey project. Diverse demand one stop to meet! Supporting cold storage products with cooling water system to meet the dairy products, beer and other light industry diverse needs. Sea and land to eat to ensure the quality of fish and shrimp! Provide on board and onshore fish and shrimp processing supporting the cooling and quick-frozen products, stable and reliable products to York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd frozen food business filled with full.

Hot summer experience! Not only in the game-type ice rink and entertainment ice rink unique advantages, but also for the automatic ice-making plant and ice cream factory to provide frozen solution.