Brand Name: York,Johnson controls

Model Number: RXF,RWFII,RWKII

Place of Origin: Jiangsu, China (Mainland)

Low Charge Central System

Efficiency and Reliability of a Central System With

The Ingenuity of Remote Distributed Condensing Units

The Low Charge Solution.

From a Single Source.

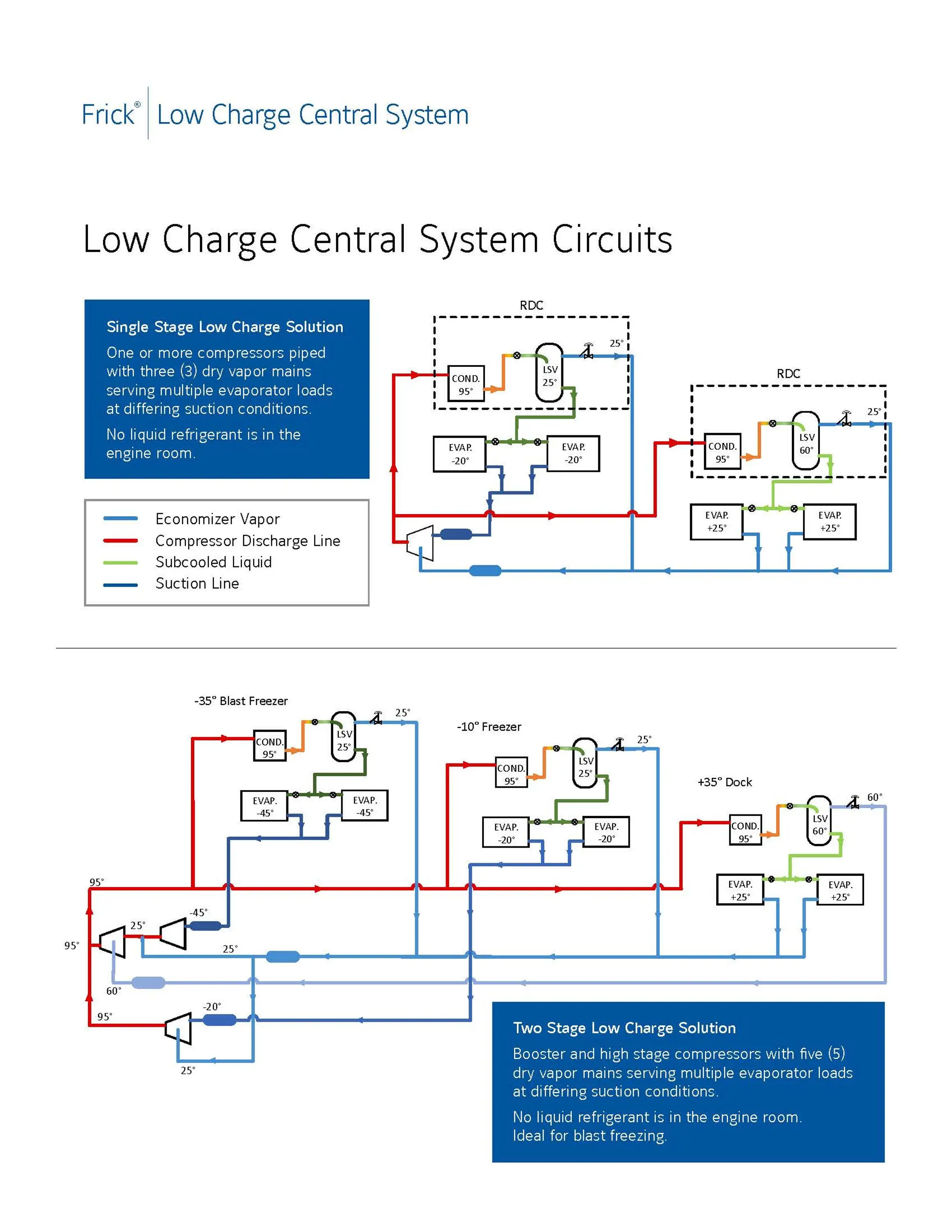

The Frick® Low Charge Central System (LCCS) combines

the high efficiency and reliability of a central refrigeration

system with innovative remote distributed condensing

(RDC) units.

This configuration results in a total system ammonia

charge of approximately 1.5-3 lbm/TR. Frick offers a complete

low charge solution with compressors, evaporators,

condensers, and controls.

Top: Standard RDC units

Middle: DX evaporators

Bottom: Charge a 50 TR RDC unit

with 75 lbm from an ammonia

cylinder in as little as 15 minutes

Advantages

n Significantly reduces ammonia charge

n Lowest total cost of ownership of any low charge system

n Minimal liquid in occupied space

n Eases regulatory burden

n Flexibility: Single and/or two stage, economized, side loads

n Easy expansion capabilities

n Capacity redundancy

n Addresses water scarcity issues without water treatment

concerns, with adiabatic or air cooled condensing

n Ease of system start up after power disruption

n Multiple heat recovery possibilities

n Compressor wiring, maintenance and oil cooling

are in the engine room

n Retains familiar industry components

n Frick Factor customization, installation and service

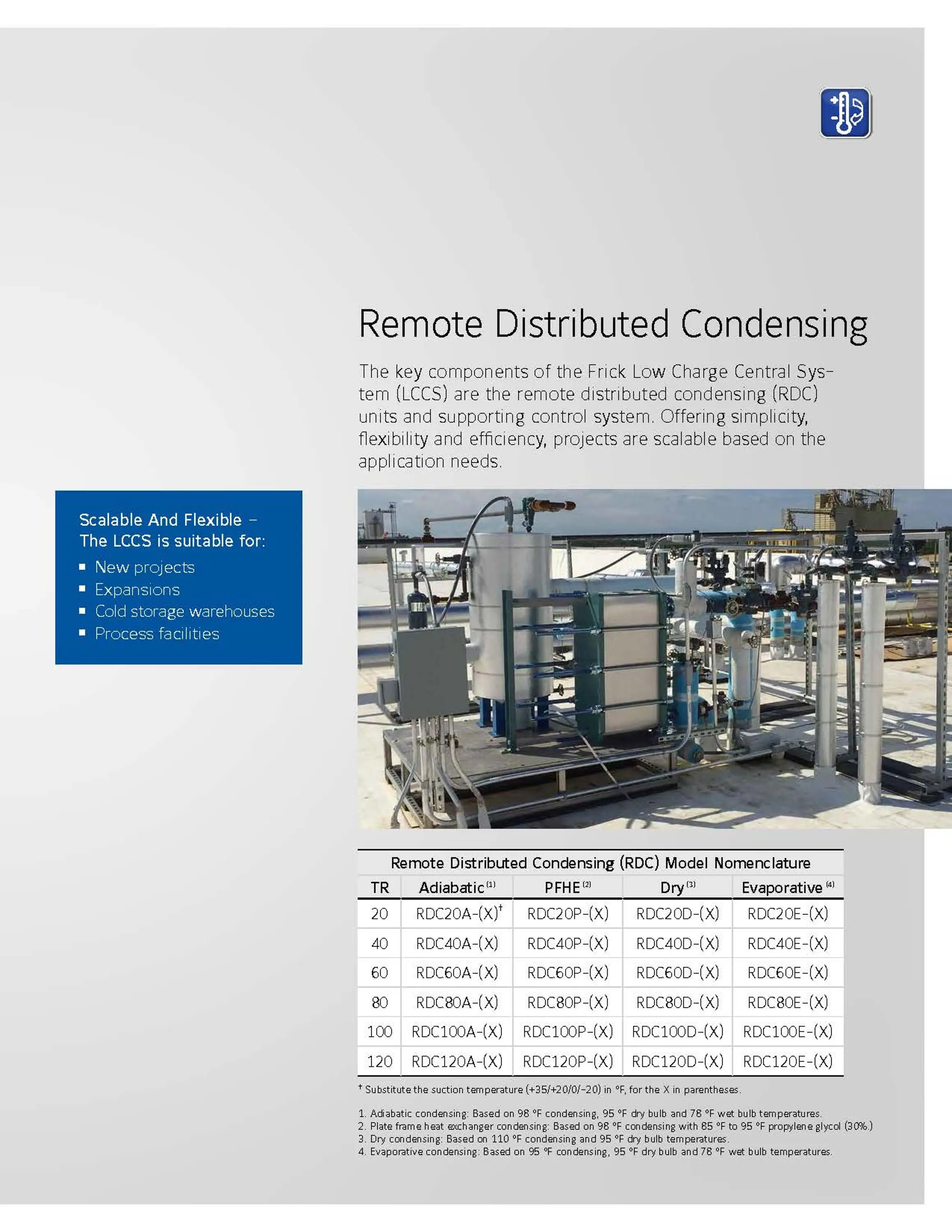

RDC20D-(X) RDC20E-(X)

40 RDC40A-(X) RDC40P-(X) RDC40D-(X) RDC40E-(X)

60 RDC60A-(X) RDC60P-(X) RDC60D-(X) RDC60E-(X)

80 RDC80A-(X) RDC80P-(X) RDC80D-(X) RDC80E-(X)

100 RDC100A-(X) RDC100P-(X) RDC100D-(X) RDC100E-(X)

120 RDC120A-(X) RDC120P-(X) RDC120D-(X) RDC120E-(X)

† Substitute the suction temperature (+35/+20/0/-20) in °F, for the X in parentheses.

1. Adiabatic condensing: Based on 98 °F condensing, 95 °F dry bulb and 78 °F wet bulb temperatures.

2. Plate frame heat exchanger condensing: Based on 98 °F condensing with 85 °F to 95 °F propylene glycol (30%.)

3. Dry condensing: Based on 110 °F condensing and 95 °F dry bulb temperatures.

4. Evaporative condensing: Based on 95 °F condensing, 95 °F dry bulb and 78 °F wet bulb temperatures.

Remote Distributed Condensing

The key components of the Frick Low Charge Central System

(LCCS) are the remote distributed condensing (RDC)

units and supporting control system. Offering simplicity,

flexibility and efficiency, projects are scalable based on the

application needs.

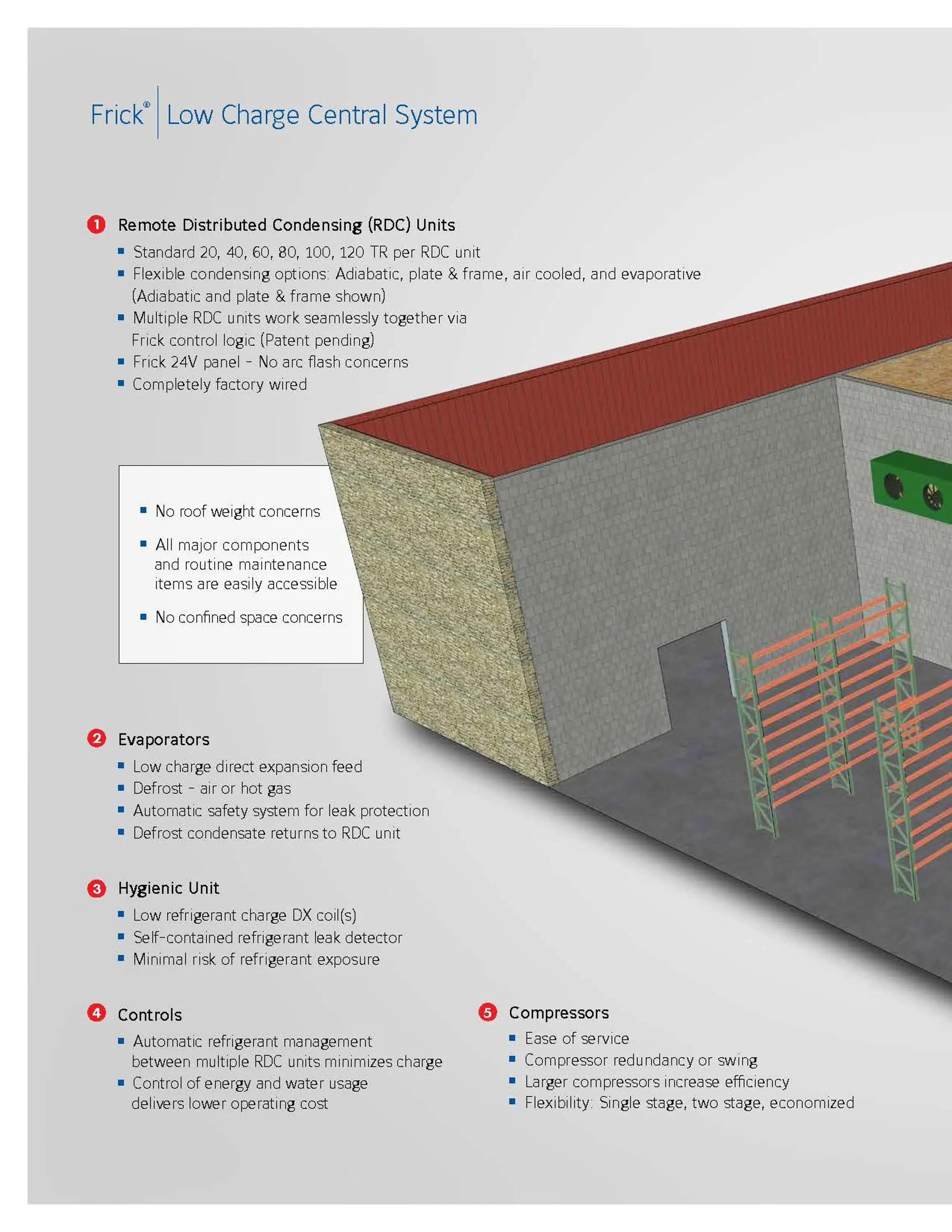

Remote Distributed Condensing (RDC) Units

n Standard 20, 40, 60, 80, 100, 120 TR per RDC unit

n Flexible condensing options: Adiabatic, plate & frame, air cooled, and evaporative

(Adiabatic and plate & frame shown)

n Multiple RDC units work seamlessly together via

Frick control logic (Patent pending)

n Frick 24V panel - No arc flash concerns

n Completely factory wired

Compressors

n Ease of service

n Compressor redundancy or swing

n Larger compressors increase efficiency

n Flexibility: Single stage, two stage, economized

Frick® I Low Charge Central System

1

2

3

4 5

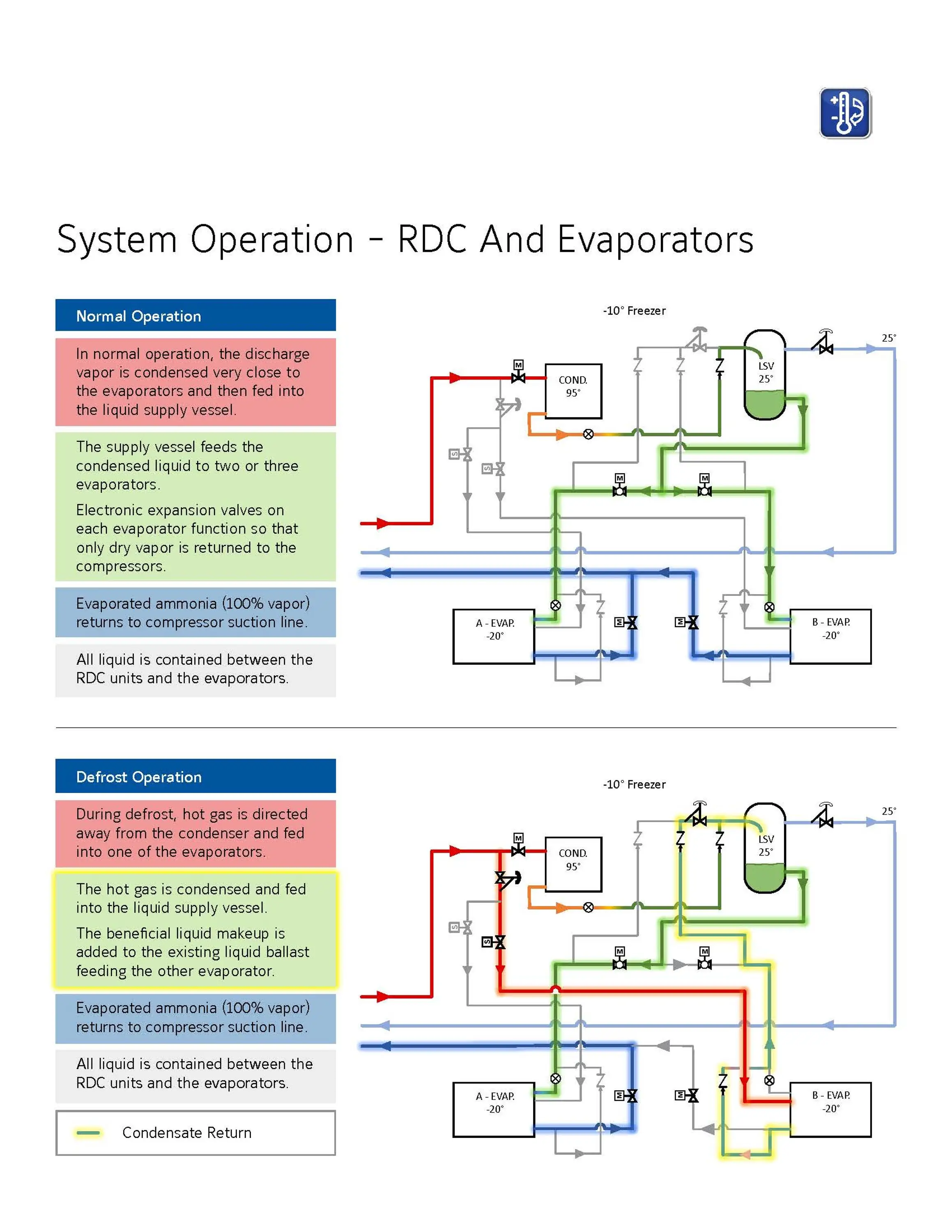

Evaporators

n Low charge direct expansion feed

n Defrost - air or hot gas

n Automatic safety system for leak protection

n Defrost condensate returns to RDC unit

Hygienic Unit

n Low refrigerant charge DX coil(s)

n Self-contained refrigerant leak detector

n Minimal risk of refrigerant exposure

Controls

n Automatic refrigerant management

between multiple RDC units minimizes charge

n Control of energy and water usage

delivers lower operating cost

zhanqinhao

HVAC&R Engineer

Refrigeration and Process Systems

China Refrigeration (York by Johnson Controls)

Mobile:+86 13818154378 18625150627

QQ: 826554493

862417098

Johnson Controls York Industrial Refrigeration - Shanghai Jiusui-Ref Systems Engineering Co., Ltd.: harsh industrial environments breakthrough in industrial refrigeration + accuracy + = large cooling load fluctuations York - Shanghai nine ear refrigeration systems engineering company tailor-made industrial refrigeration systems!

Provide personalized solutions for five major areas! Can be mainly used in petroleum, petrochemical process; chemical technology; synthetic rubber technology; fertilizer production process and chemical fiber textile technology. A number of other applications to meet different needs!

In addition to the above five major areas, York-Shanghai Nine Sui Refrigeration Systems Engineering Company Industrial refrigeration approved for use in air separation plants, liquefaction plants, carbon dioxide recovery systems, pharmaceutical industry, tobacco industry and steel plants, power plants, electronics factories and other process cooling And refrigeration systems.

York Nine Sui Refrigeration Systems Engineering Company is located in the petrochemical industry, whether it is upstream natural gas compression, midstream liquefied natural gas storage, transshipment, or downstream air separation, liquefaction unit, as long as the compression-related York-Shanghai nine-pan refrigeration system Engineering companies are involved!

Advanced control system + energy efficient refrigeration equipment + overall solution = York - Shanghai Jiusui-Ref Systems Engineering Co., Ltd a full range of food refrigeration business!

Food processing + large cold storage + poultry slaughter + beer drinks + dairy products + aquatic fisheries + small logistics distribution center, etc. = York - Shanghai nine Sui refrigeration systems engineering company food refrigeration business coverage!

P.K. "China cold village" -58 ℃ low temperature! (-28 ℃ ~ 15 ℃), and even tuna low-temperature cold storage (-55 ℃ ~ -60 ℃), York - Shanghai nine Sui refrigeration systems engineering company food refrigeration business can be, but also the production of cold storage, Complete turnkey project. Diverse demand one stop to meet! Supporting cold storage products with cooling water system to meet the dairy products, beer and other light industry diverse needs. Sea and land to eat to ensure the quality of fish and shrimp! Provide on board and onshore fish and shrimp processing supporting the cooling and quick-frozen products, stable and reliable products to York - Shanghai nine Sui refrigeration systems engineering company frozen food business filled with full.

Hot summer experience! Not only in the game-type ice rink and entertainment ice rink unique advantages, but also for the automatic ice-making plant and ice cream factory to provide frozen solution