Brand Name: JINKETONGLI

Model Number: Butterfly Valve

Place of Origin: Hebei, China (Mainland)

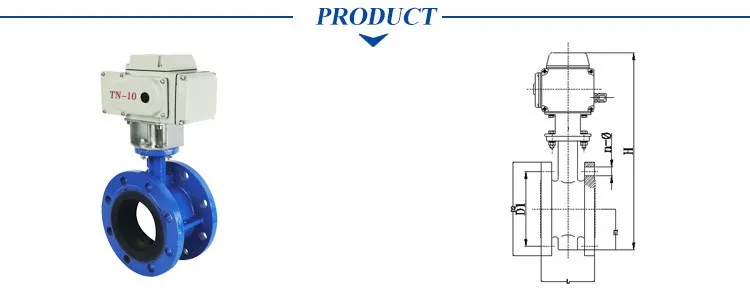

Flange type motorized butterfly valve AC220v electric butterfly valve

Body |

Materials |

| Cast Iron: ASTM A126CL. B , DIN1691 GG25, EN 1561 EN-GJL-200, GB12226 HT200; | |

Ductile Cast Iron: ASTM A536 65-45-12, DIN 1693 GGG40, EN1563 EN-GJS-400-15, GB12227 QT450-10; |

|

| Stainless Steel: ASTM A351 CF8, CF8M, CF3, CF3M; | |

| Stem | Carbon Steel: ASTM A216 WCB |

| Zinc Plated Steel; | |

| Taper Pin | Stainless Steel: ASTM A276 Type 316, Type 410, Type 420, ASTM A582 Type 416; |

| Seat | Stainless Steel: ASTM A276 Type 304, Type 316, EN 1.4501; |

| Disc

|

NBR, EPDM, Neoprene, PTFE, Viton; |

Ductile Cast Iron (Nickel plated): ASTM A536 65-45-12, DIN 1693 GGG40, EN1563 EN-GJS-400-15, GB12227 QT450-10; |

|

| Stainless Steel: ASTM A351 CF8, CF8M, CF3, CF3M, EN 1.4408, 1.4469; 1.4501; | |

| AL-Bronze: ASTM B148 C95400; | |

| O-Ring | NBR, EPDM, Neoprene, Viton; |

| Bushing | PTFE, Nylon, Lubricated Bronze; |

| Key | Carbon Steel |

This buyer can select material as per materials list. The customer may mark the material and temperature used, Our company may select instead. When the medium and temperature is special, please consult with our company. |

|

| Seat Temperature Ratings | |||||||

| Material | NBR | Neoprene | EPDM | Hypalon | Viton | PTFE | |

| Temperature Ratings | °C | -20~100 | -40~100 | -40~120 | -32~135 | -12~230 | -50~200 |

| °F | -4~212 | -40~212 | -40~248 | -25.6~275 | 10.4~446 | -58~392 | |

Seat materials are capable of withstanding lower temperatures without damage. However, the elastomer becomes hard and torques increase. Some flow media may further restrict the published temperature limits or significantly reduce seat lif |

|||||||

Key Actuator Specifications and Benefits:

1. Reversing Motors, Thermal Overload Protection, 30% Duty rated long life.

2. Four (4) Limit switches for Motor Control and Remote Indication of End of Travel.

3. Adjustable mechanical travel stops and Local visual position indication.

4. 220 V ac, single phase standard. Additional voltages available including: 220 V dc single phase,12 V dc,

24 V dc, 24 V ac.

Actuator Mounting

Note:

Prior to mounting,the part-turn actuator must be checked for any damage

Damaged parts must be replaced by original spare parts

Mounting ia most easily done with the valve shaft pointing vertically upward.But mounting is also possible in any other position ;the actuator may be mounted in any position.

The QT-series electric actuators are supplied with a female drive output.the ISO5211 bolt patterns are provided for actuator mounting.The actuator drive bush is removable for ease of machining.

It is mandatory for the actuator to be firmly secured to be a sturdy mounting bracket or directly mounted to be valves' ISO mounting pad.High tensile bolts or studs with spring locking washers must be used.

The valve outpot shaft must be in lined with the actuator output drive to avoid side-loading the shaft .To avoid backlash,flexibility in the mounting bracket or mounting should not be allowed.

We use high quality plywood wooden case packing which avoid fumigation.It have good cushioning performance,

high strength,and corrosion resistance.The use of foam film cover the valve better to protect the valve body and

fixing wooden cases is the final step.