Brand Name: sindeice

Model Number: sdwf-3t

Place of Origin: china

Sindeice 3ton snow flake ice machine for frozen fisheries

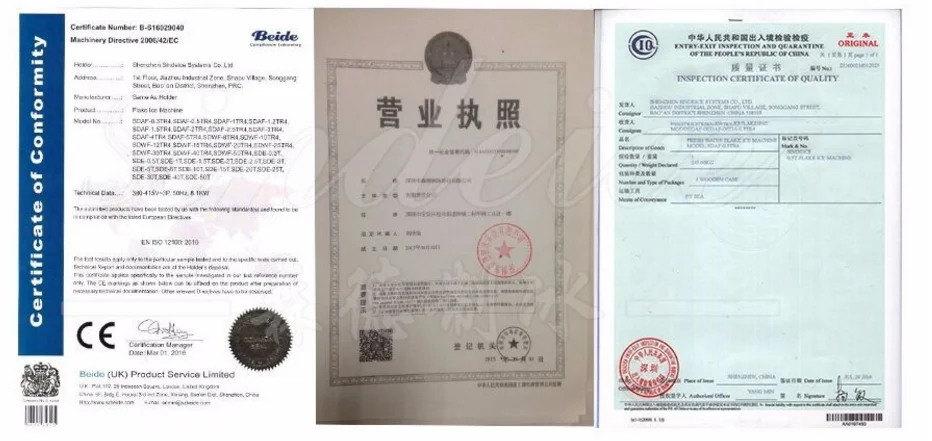

Company Overview

SHENZHEN SINDEICE SYSTEMS CO., LTD (Sindeice for short) is a professional manufacturer of ice machines, who has a set of research, design, production, installation, sale and after-sales service. We got a number of experienced experts who engaged in refrigeration and ice machine for many years. With the use of best technology of ice machine and innovative solutions, Sindeice manufactures Flake ice machine, Tube ice machine, Block ice machine, Ice flaker evaporator, Containerized ice plant. Daily capacities are available from 300 kg to 100,000 kg.

Sindeice is sticking to the notion of “great virtue,social commitment”, and the management policy of “integrity, diligence, innovation and mutual benefit”.Sindeice strives to enter into international market.

Product Description

For the flat and thin shape, flake ice is excellent in area contact and fast temperature Cooling. It’s easy and fast to produce flake ice without ice crusher but saving cost.

Appearance can be customized, components are optional, Sindeice Systems is a professional of machine building.

Standard Working Conditions and specifications

1.Ambient Temp 25℃

2.Inlet Water 18℃

3.The evaporating temperature is -20℃

4.The condensing temperature is 40℃

5.Water Inlet Pressure 0.1MPa~ 0.5MPa

6.Ice thickness 1.5~ 2.2mm

7.Power Supply 3P/380~420V/50/60Hz or according user's requirements

8.Refrigerant:R404a/R22

9.daily output 3t

10.refrigerating capacity 17.41kw

11.total power 11.06kw

12.compressor power 9.67kw

13.cooling way: air cooling

14.operating weight:600kg

15.dimensions of unit: 1830*1200*1200mm

16.dimensions with ice bin:1830*1635*2600mm

Application areas

Application of flake ice machine

Vegetable & Fruit preservation and transportation

In whatever development stage of mechanical refrigeration technology, it provides just cold temperature while moist environment is still void. Flake ice, with its physical characteristics, is to cool down the temperature as well as to provide sufficient water. Till now, there is no ideal replacement to supplant flake ice in this regard. So vegetables and fruits will be kept from rotting and dewatering with the presence of flake ice in the process of storage, transportation and display. Flake ice will help with long time keeping of fruit and vegetable.

Meat and Sausage Processing

In order to prevent fungi from quick propagation and to prevent the meat from getting dark and degreased because of high temperature caused in the process of sausage and ham making, a proper dose of clean and hygienic flake ice can be added to lower the temperature as this may raise the hygiene level of meat.

Sea Food Industry

Flake ice is widely used in a variety of sea food processing fields as it can provide sufficient water, and cool down the temperature in the process of melting. At whatever stage in the development history, mechanical refrigeration systems offer only cold temperature instead of moist surroundings, which is normally causing dry surface and dehydration of sea food, and reducing the freshness of sea food. While flake ice is able to provide a perfect cooling surrounding, which keeps the sea food in an ideal cold and moist status. Flake ice can prevent sea food from turning rotten and degenerate, furthermore, it may avoid cases of dewatering and dry surface. The melting ice water washes the surface of sea food, which helps reduce the content of fungi and suppress odor and reaches the ideal fresh keeping effect.

Fowl/poultry Slaughtering

In the process of bird & poultry processing, unhairing is normally done by vaporizing. High temperature may soften the poultry’s fat which is subject to rotting. So the poultry shall be cooled down immediately after unhairing to ensure the product’s freshness. Flake ice is added to the water in the screw chiller which keeps the water in a temp range of 0 –4 degrees Celsius. After cooling down in the cold water in the screw chiller, the poultry will be put in refrigerated room. Research results show that poultry treated in this way will be prevented from germ contamination.

Industries of Chemical Dye

In the composition process of biological pharmacy, chemical pharmacy and medication, a proper doze of ice is added to manipulate the temperature at which chemical reactions happen and keep the biological activation. Flake ice is hygienic and even in shape. And flowing characteristic and its sufficient unit contact area make it a most ideal temperature cooling media in chemical medication industry.

For example, in the composition process of pigments, diazotization, coupling and condensation are the three prerequisite steps.As huge amounts of heat will be released in the process of diazotization, coupling and condensation, while the ideal reaction condition is 0 – 5 degrees Celsius, plentiful flake ice will be added to manipulate the temperature so as to assure the product’s quality.

Real Photos

1.Package contents: 1)Mchinery unit 2)User Manual 3)Ice bin (Optional) 4) Cooling system

5)Wooden plate

2.Lead time: 5~10 days,For more details, Pls turn to our sales reppresentative.

3.INCO Terms: EXW, FOB, CIF, C&F, DDU, DDP and so on, Since our factory is located in Shenzhen, China which is one of the biggest export city in Asia, we will try our best to meet your requirements about Logistics.

4.Assemble all the machine components , connect the power and water to the machine according to the installation book, it is easy to handle by any electrical or refrigeration technician, if any question you can call us at any time, our engineers will help you to fix it out. If you need our engineers going to the site for instruction, buyer should pay for visa fee, trip cost, expense of labor and accommodation.

Installation and maintenance

1. Installation:

1). Installing by the user: we will tested and install well the machine before shipment, all necessary spare parts and operation manual are provided to guide the installation.

2). Installing by SINDEICE engineers:

(1) We can send our engineer to assist the installation and provide technical support and train your workers. The end-user provide accommodation and round-trip ticket for our engineer.

(2) Before our engineer arrived in your site, the installation place, electricity, water and installation tools should be ready. Meanwhile, we will provide you a Tool List with the machine when delivery.

2.Maintenance

To lengthen the lifetime of an ice machine and increase the efficiency for energy-saving purpose, a regular check on the ice machine is quite necessary. User is suggested to make a daily/weekly/monthly/quarterly/yearlyrecord of maintenance and servicing and a very detailed log of the damage servicing so that servicing personnel can properly trace the failure history during trouble shooting process.

Daily Maintenance

Start and Stop the machine as instructed in this manual;

Make a regular record of the parameters in operation daily;

Regular check on the Dryer Filter is necessary. If frost is found on the outlet of the Filter, that may mean jamming inside the Filter. This symptom is normally accompanied by low evaporating pressure and higher condensing water temperature.

Check if the refrigeration oil is normal. If there is lack of refrigeration oil, add more. And if the oil is dirty and goes bad, change it and clean the oil filter and change to a new filter core.

When there is lack of refrigerant, to prevent frequent turn-off of the machine, the capacity status should be set to a partial load. After refrigerant is filled, set the capacity status to full load.

Any failure occurrence should not go unnoticed. A thorough analysis should be done for the cause of failure. Make a thorough analysis of the failure may help with finding a solution to the problem. And notice the SINDEICE after-sale service department of the analysis that is done.

Regular Maintenance

Regular maintenance includes maintenance on a weekly/monthly/quarterly/yearly basis. User can refer to the following scientific maintenance scheme and carry it out in a strict manner. That may help with prevention of failures in a substantially crucial way.

Weekly maintenance

Check and make an analysis of the parameters of ice machine in operation.

Monthly maintenance

Check and make an analysis of the record of parameters of ice machine in operation;

Check the bolts fastening the power wires are always tight;

Check and confirm there is no noise on all moving parts of the ice machine, and there is no abnormality in operation;

Check the water system is working properly;

Check the Compressor’s oil heater is working properly;

Check the High & Low Pressure is normal;

Check the operation current of compressors and motors is normal; check the resistance is normal. If the resistance is lower than 5 MΩ, stop the machine immediately.

Check the water tank/freezing surface/ice storage bin/water distributing tubes/condenser’s fins regularly and clean the dust and dirty things.

FAQ

Q1: What are the payment terms?

A: We usually accept payment by T/T, L/C.

Normally, we accept 30% Deposit and 70% balance paid before delivery.

Q2 : Can any of the products be custom imprinted?

A: If you need to print your company logo on the products and that is available to be customized. Or if you have your own designed idea and that will be our honor to customize for you.

Q3: How to ensure that I received the machine undamaged?

A: At first , our package is standard for shipping, before packing, we will confirm product undamaged, otherwise, please contact within 2days. Because we've bought insurance for you, we or shipping company will be responsible!

Q4: Do I need to install the ice machine by myself?

A: For small ice machine, we ship it as a whole unit. So you just need to prepare power and water to run the machine.

For some larger ice machine plant, we need to keep some components seperate for shipping convenience. But no worris about that. An installation brochure will be sent to you,it's very to install the machine.

Q5:What is the warranty for ice making machine?

A: 18 months after B/L date. Any failure occurred within this period due to our responsibility, we'll supply you the spare parts for free and permanent technical support &consultation all life long for ice making machines.