Brand Name: CF

Model Number: HI-PEF

Place of Origin: Guangdong, China (Mainland)

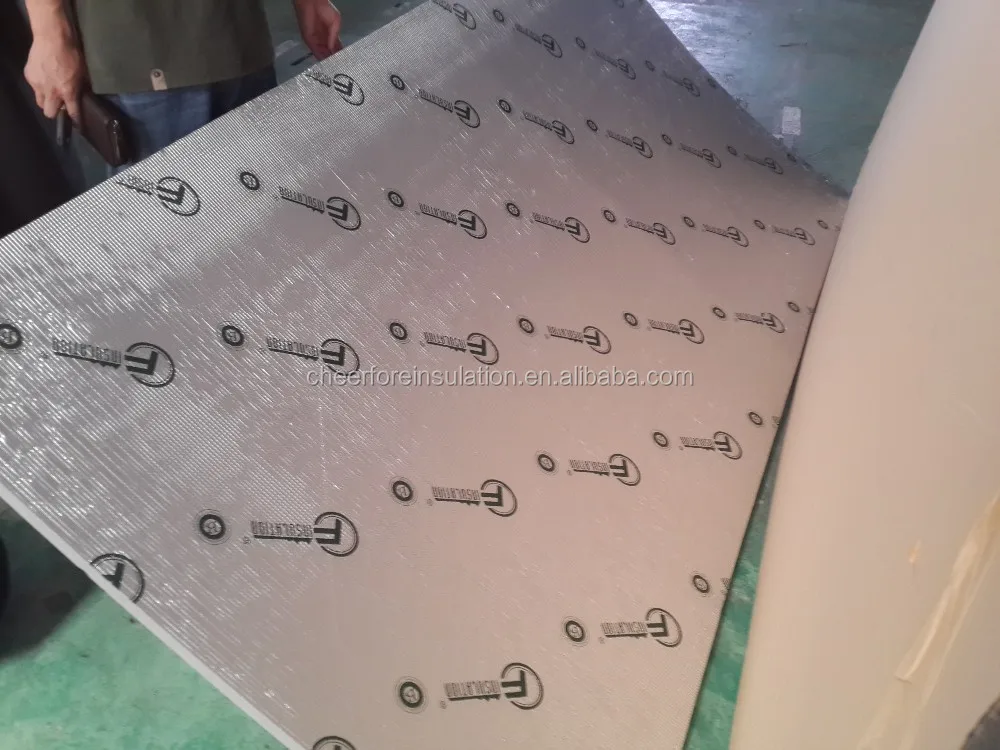

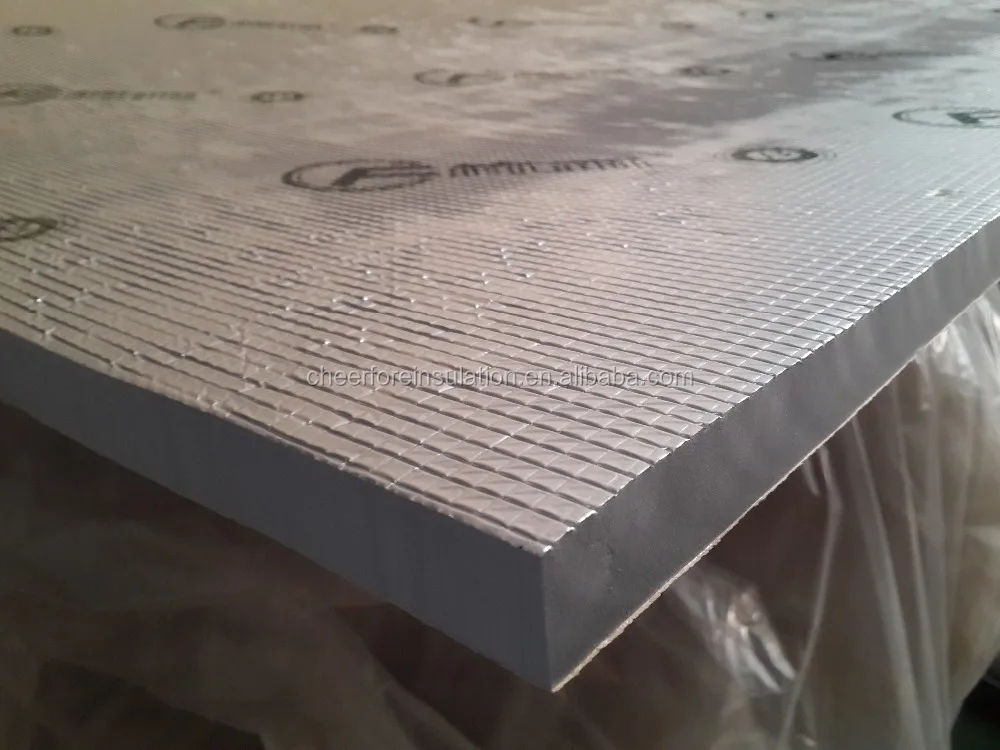

25mm Embossed aluminum foil facing PE foam

Thermal Insulation PE Foam

Polyethylene (PE) foam, full closed cell structure, is made from LDPE, flame retardants, etc., and free from PVC, gives out low smoke and non-toxic matter.

PE Foam Parameter:

| CF PE FOAM PARAMETER | ||||

| Item | Unit | Testing Standard | Parameters | |

| Surface Density | Kg/m3 | GB/T6343-1995 | 28-45 | |

| Burning Grade | —— | GB8624-1997 | B1 | |

| Burning Performance | Oxygen Exponent | % | GB8624-1997 | 32.8 |

| Smoke Density | % | GB8624-1997 | 50 | |

| Heating Conductivity coefficient | Average Temperature 10℃ | W/(m·k) | GB3399-1988 | 0.0327 |

| -20℃ | —— | |||

| 0℃ | ||||

| 40℃ | ||||

| Moisture Penetration | Coefficient | G/(m·s·pa) | GB/T 17794-1999 | ≤2.4×10-10 |

| Moisture Resistance | —— | GB/T 17794-1999 | 8.1×102 | |

| Water Absorption in Vacuum | g/cm3 | GB/T 1034-86 | 0.0019 | |

| Dimension Stability | % | GB/T8811-1988 | 0.66 | |

| 70℃ ±3℃,48h | ||||

| Rebound Rate after Compression | % | Q/(GZ) HD1-2003 | 96 | |

| Ripping Intension | N/cm | GB/T 10808-1989 | 3.3 | |

| Ozone endurance Ozone Suppressor202mPa,200h | —— | GB/T 17794-1999 | No Chaps | |

| Aging Resistance(150h) | —— | GB/T 17794-1999 | No Wrinkle | |

| No Crack | ||||

| No Pinhole | ||||

| No Distort | ||||

| Temperature Range | ℃ | -50~+90 | ||

PE foam sheet size:

Wall (Thickness) |

1/8” (3mm) |

1/4" (6mm) |

3/8" (9mm) |

1/2" (13mm) |

5/8”(16mm) |

3/4” (19mm) |

1” (25mm) |

1 1/4” (32mm) |

1 1/2” (38mm) |

2” (50mm) |

Width |

1.0 or 1.2m |

|||||||||

Length |

2.0m or 1.2m |

|||||||||

pcs/ ctn(bag) |

80 |

40 |

26 |

20 |

16 |

14 |

10 |

8 |

7 |

5 |

PE Foam Characteristics:

1.Flame retardent

2.Self adhesive available

3.Aluminum foil composite available

4.No hazard to health

5.Easy installation

6.Waterproof and Fireproof

Thermal Insulation PE Foam Application

1.Refrigeration Medium System

2.Air Duct System

3.Chilled Water System

4.Condensed Water System

5.Hot Water Piping System

High quality exporting package-paper carton or PE bag.

Shiping:

7-15days after depoist FOB(Guangzhou/Shenzhen)

Quality Control:

we always pay more attention to the raw material quality, standard quality control system and team are responsible to ensure the product quality in every process with different machine like extrusion equipment and mould pressing equipment.

1).The quality of our products all through the QC staff to check.

2).All of our products get through strictly quality system to control it, after four re-check before shipment, including purchasing materials, production processes, processing and packaging.

3).National Institute of Standards by SGS product certification testing.