Brand Name: OEM Fins Heating Tube

Model Number: DT-ASE-04

Place of Origin: Guangdong, China (Mainland), Guangdong China (Mainland)

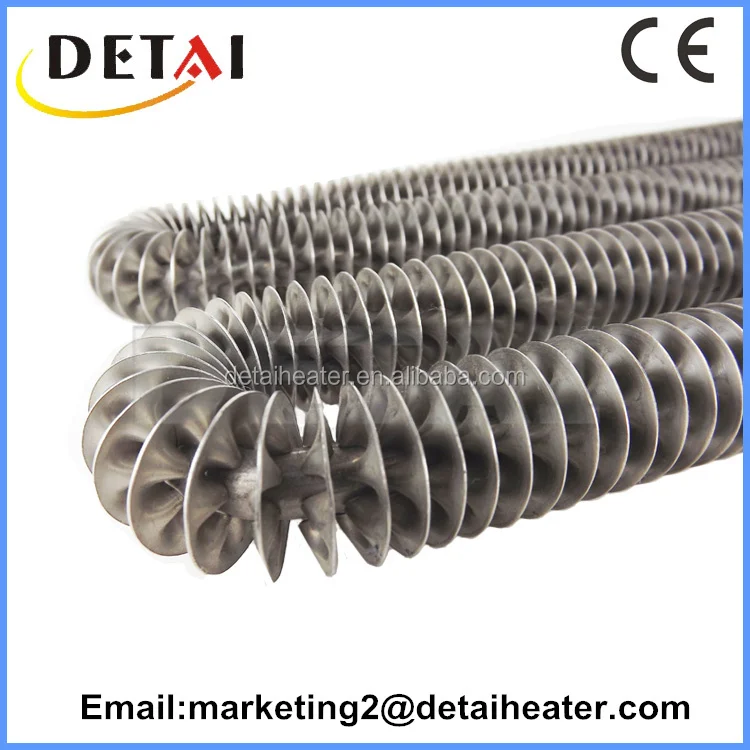

Introduction of Fins Heating Tube

A corrugated metal fin is helically wound on a tubular element to improve heat transfer in air applications. Depending on the sheath and fin material selected, the fins are either permanently attached, mechanically or via furnace brazing. The entire assembly then goes through a computer controlled atmosphere furnace. This process prepares the element to be bent into a variety of configurations. Standard fin density is five fins per inch, while eight fins per inch can be furnished when specified for lower sheath temperatures.

Technique Data of Fins Heating Tube

Sheath Material |

SUS 304/316/ Incoloy 840 |

Spirals |

Nickel - Chrome |

Insulation |

Magnesium Oxide Powder |

Voltage & Watt Supply |

50V-450V & 100W-10KW |

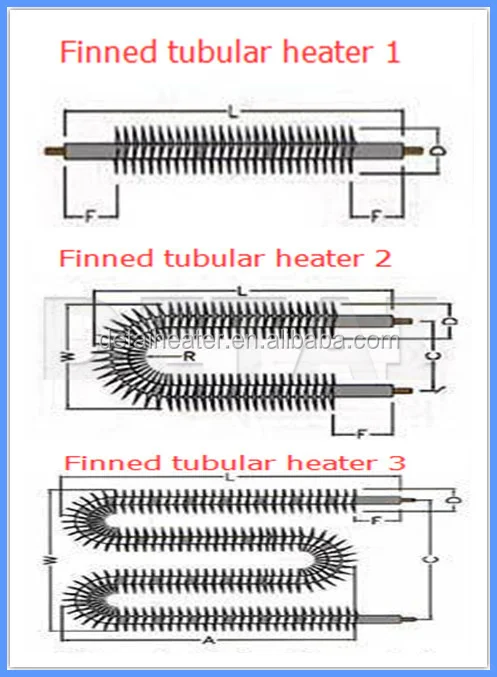

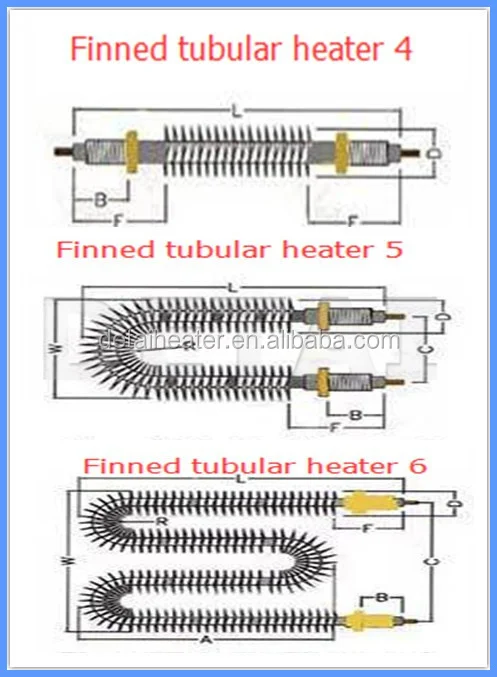

Shape |

U Shape/ W Shape/ I shape |

Resistance Tolerance |

+10% - 5% |

Wattage Tolerance |

+5% - 10% (closer tolerances are available upon special request) |

| Material | Details of contents | Proper environment | Limit service temperature |

| SUS304 | Ni 8.0~10.5 | Air heating | 600°C or less |

| Cr 18.0~20.0 | |||

| Ti ---- | |||

| Mn 2.00MAX | |||

| Mo ---- | |||

| Incoloy 840 | Ni 18.0~22.0 | 800°C or less | |

| Cr 18.0~22.0 | |||

| Ti 0.6MAX | |||

| Mn 1.00MAX | |||

| Mo ---- | |||

| Incoloy 800 | Ni 30.0~35.0 | 260°C or less | |

| Cr 19.0~23.0 | |||

| Ti 0.15~0.6 | |||

| Mn 1.5MAX | |||

| Mo ---- |

Features of Fins Heating Tube

1. Versatile — Ideal for both comfort and industrial process air applications. Stainless Steel (FTSS) sheath and fin material are available.

2. Fins greatly increase surface area and permit faster heat transfer to the air, resulting in lower element surface temperatures.

3. Construction — Element is constructed like the standard tubular element with the addition of continuous spiral fins (4 - 5 per inch) permanently furnace brazed to the sheath.

4. High Watt Density permits use of fewer elements or higher concentration of installed kW for a given area.

5. Easy Installation — Bending configurations can be designed to fit either round or rectangular ducts. Tight element bends are repressed in hydraulic presses after bending to assure recompaction of refractory material to eliminate hot spots and electrical insulation voids.

6. Power Connections should be made with alloy wire.

7. Over temperature Protection — A high limit temperature cut out is recommended.

8. Bending — Finned tubular elements may be field or factory bent according to the following parameters: I Shape, U Shape and W Shape

9. Special Terminal Construction — Many types of terminals are available to suit different applications.

Applications of Fins Heating Tube

1. Drying

2. Heat Treating

3. Annealing

4. Load Banks

5. Curing Ovens, Dryers, Ducts, etc.

6. Microwave oven ranges, panel heaters, baseboards, and heaters

When you order Fins Heating Tube, please note the specifications as follows:

1,Any drawings or photos will be very helpful

2,Power,voltage,shape

3,Working temperature

4,Material requirement

5,Quantity

6,Othe requirement required.

Packaging&Shipping

Detailed Pictures

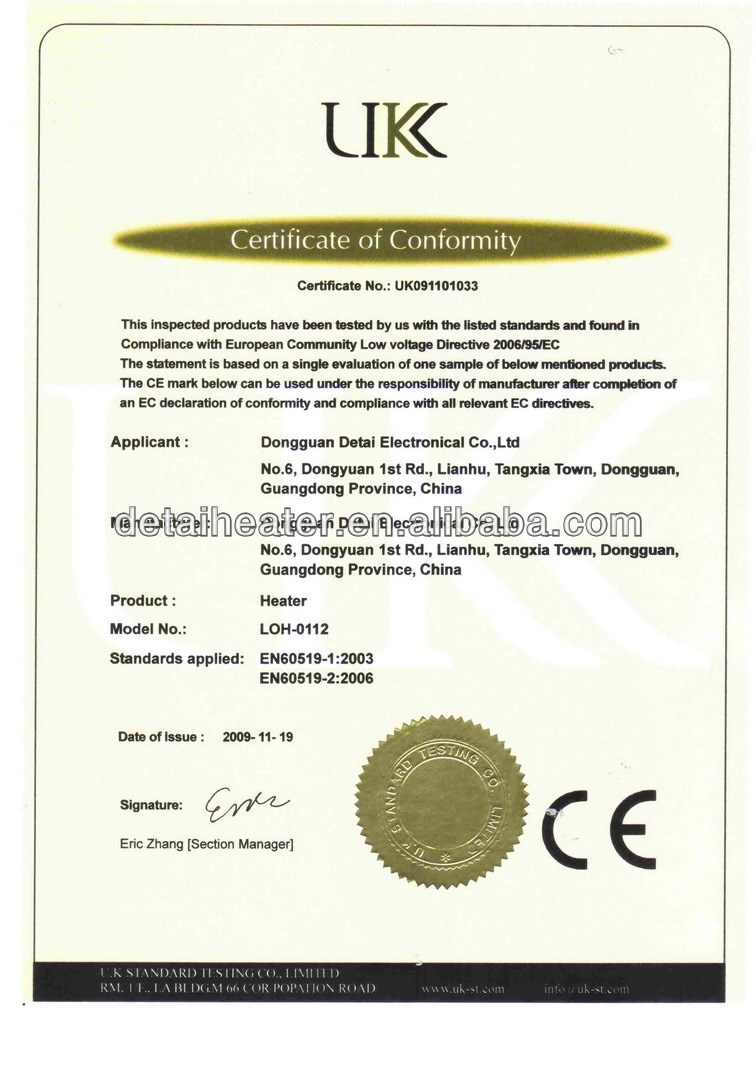

Certifications:

Exhibition

Contact Now:

Hi, this is Cathy. Email, skype, or call me anytime if have you have any questions or problems!

Email: marketing2 (at) detaiheater.com

Skype: Cathy_heating element

Address: A1-301, Shiye Rd#28, Zhufoling Village, Tangxia Town, Dongguan City, 523721, China