Brand Name: Yuanda Boiler

Model Number: DZL

Place of Origin: Henan, China (Mainland)

1.Model:DZL DZH(we also have SZL SZH)

2.Capacity:1-20ton/h

3.Pressure:1.0Mpa(10bar),1.25Mpa(13bar),1.6Mpa(16bar),2.5Mpa(25bar)

4.Steam temperature:184 °c,194°c, 204°c,226°c(As long as the steam temperature you need is lower than 226°c, we can do it).

5.Fuel:coal,biomass

6.Structure:horizontal water-fire tube, single drum

7.Type:we have two types.One is DZL chain grate stoker automatic feeding fuel and removing dregs type. Another is DZH hand operate moving grate type which needs labour to feed fuel and remove the dregs.

8.Application:industrial production and processing.

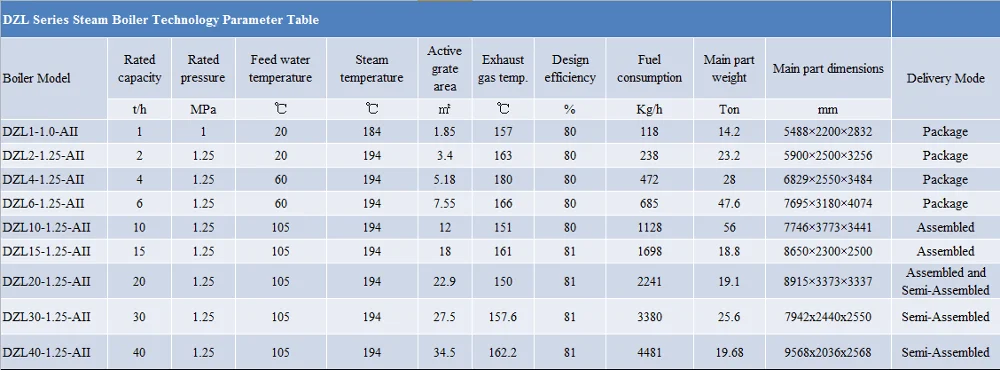

Technical datasheet

Characteristics

I. Sufficient and Steady Capacity

With efficient diabatic spirally corrugated tube, it is designed by using heat transfer and flow resistance technologies of Harbin Institute of Technology. The boiler’s actual capacity is 10-15% higher than name plate capacity. As the physical dimension and smoke speed of the spirally corrugated tube are rational, and the spirally corrugated tube doesn’t form soot or wear when the boiler normally operates, the boiler’s capacity and heat efficiency don’t reduce with the extension of operating time;

II. Rapid Warming and High Heat Efficiency

The main heating surface is installed in the shell, so it doesn’t leak cold air to the smoke side, and nearly a half of shell surface is heated. The boiler’s heating up time is one third shorter than other furnaces, and heat efficiency is the highest in various furnaces;

III. Low Original Dust Discharge Concentration, Environmental Protection and Energy Conservation

It uses new arch and hearth with large volume, the rear of the hearth has a dust separation reversing chamber, and the unburned dust particles fall to the hearth for secondary combustion, corresponding to primary dedusting in the furnace. Therefore, it ensures that the original dust discharge concentration is lower than national permissible value, reducing fuel consumption, and protecting the environment;

IV. High Steam Quality

The optimally designed feeding apparatus reduces overhigh water level in shell high temperature zone due to overheat; the optimally designed steam separator facilitates vapour gravity separation, and makes the steam humidity lower than 1%, obviously lower than national standard of 4%;

V. Strong Water Quality Adaptability

By adopting the advanced water circulation technology, it improves water circulation speed of high temperature zone, increases the flow of bottom water, and avoids sundries deposition and scaling, with stronger water quality adaptability than other furnaces, reducing fuel consumption, and improving operating time;

VI. Small Overall Dimensions and Low Boiler Room Investment Cost

The main heating surface is installed in the shell, and small capacity boiler can cancel the rear heating surface. Its overall dimension is obviously smaller than other boilers. The boiler below 100tons (70MW) can be arranged in single layer, making the investment of the boiler room save more than 50% than other types;

VII. Low Operating Cost, Safety and Reliability

The adoption of advanced water circulation technology and optimization of boiler structure improve the operating conditions of the high temperature tube plate, water wall tube and shell bottom. In normal water quality condition, it doesn’t cause tube explosion, tube plate cracking or shell bottom bulge. As the boiler has large water capacity, it doesn’t need special protective measures in sudden power failure, and prevents damage accidents of heating surface and shell medium due to vaporization. The safe reliability is guaranteed, and operating cost is far lower than other furnaces;

VIII. Short Installation Time, Low Installation Cost

There are fast-delivery, assembly and semi-assembly type delivery model. the installation period and cost can be lower by over 30%.

Fast Package Naked for main part (Boiler Host), wood case for auxiliary.

1.Nude packaging for boiler mian part and wood box packaging for boiler accessories.

2.Normally we use 20 container, 40container or 20 flat rack container and 40 flat rack container to load it.

3.All goods will be reforced after packing into containers.

4.We have stable shipping company to cooperate. They will confirm the safty of the goods.

5.Shipping way is different according to customer's country. Mostly by sea. Some country by train.

One-stop service

You only need to provide what you need, and the rest,We will provide product design,manufacturing, transportation, installation team installed faction, guide the operation and so on. We guarantee to provide you with satisfactory service.

Warranty :

1.two-year warranty and full-life service for all our steam boilers.

2.61 years professional boiler manfuacturer since 1956.

3.X-ray test before delivery to guarantee the boiler's excellent quality.

4.NDT test before delivery to assure the boiler's excellent quality.

Accessories and boiler room equipment service:

1.A full range of original spare parts are available for all yuanda boilers.

2.free boiler online installation guidance service.

The factory manufacture situation are as follows:

Henan Yuanda Boiler Co,. Ltd, founded in 1956, is one of the leading enterprises which firstly obtained boiler manufacturing license in China.

Our factory is located in the west industrial agglomeration area of Xihua county,Henan province. R & D center and marketing center are located in the capital city,Zhengzhou, Henan Province.We are high-tech enterprise combining with research, development and sales of heating system and power system. We have B-class boiler manufacturing license(professional for industrial boilers) and D-class pressure vessel manufacturing license, and passed ISO9001,ISO14001 and OHSAS18001.

The factory has beautiful environment with cover area 66000m2 and building area 30000m2. We have employees more than 200 people, including engineers 30 people and senior engineer 10 people. We have advanced equipment, with 430 sets of main production equipment and 30 sets of testing equipment.

Our main products include Our main products include more than 150 kinds, namely,

1. DZL new type water fire tube boilers (1-35T/H, 0.7-29MW)

2. WNS series oil/gas fired boilers (0.3-20T/H, 0.35-14MN)

3. SZL series water tube biomass boilers (2-35T/H, 1.4-29MW)

4. LNB series gas boilers (0.3-10T)

5. LHS series vertical gas/oil fired boiler(0.3-1T)

6. AAC brick/block making machine We sell well in more than 30 provinces and regions in China and in south-east Asia, Asia, Africa, South America, Middle East, Russia, etc.

We have our own R&D team and cooperate with famous high-tech research institutes at the same time , such as Beijing "Zhiguang" boiler institute,Harbin Institute of Technology and Xi'an Jiaotong University, which ensures our product and technology are in the forefront of technology and science. Till now, we have got more than 10 boiler patents.

Welcome to visit Yuanda Boiler factory!

Q: How can you get the best price quickly?

A: As soon as the steam capacity / thermal power and pressure are told, we will make the detail price list at once.

Q: Why should you believe our quality?

A: 61 year experience, founed since 1956; Chinese-government appointed Boiler Manufacturer.

With ISO9001, CE certificates.Quality control system: Include 8 subsystems, design, techonics, welding, inspection, non-destructive testing, heat treatment, materials physics and chemistry inspection, device management Each process will be strict supervised. 5 process quality point, Raw material inspection, product specimen, NDT, hydrostatic test, Heat treatment. The products must be inspected by third party before delivery.

Q: What about the installation?

A: After you receive the boiler, we will guide you to make some preparation for installation; If necessary, our expert will fly to your local place in 72 hours. The experts will responsible for guiding installation,training, trial operation

Dear friend,

Thanks for your time for scaning our products.

We need the following information to confirm the boiler model:

1.Boiler type:steam boiler, hot water boiler or thermal oil boiler?

2.Boiler capacity?

3. Boiler pressure?

4. Boiler application?

After confirming these questions, we will know exactly what boiler will be suitable for you and we will provide you our product details and quotation,ok?

Best regards,

Mandy He

please send your inquiry details in the below. Click"send" now!