Brand Name: Yuanda Boiler

Model Number: DZH

Place of Origin: Henan, China (Mainland)

Industrial Wood Fired Thermax Steam Boiler

1.Model:DZL DZH(we also have SZL SZH)

2.Capacity:1-20ton/h

3.Pressure:1.0Mpa(10bar),1.25Mpa(13bar),1.6Mpa(16bar),2.5Mpa(25bar)

4.Steam temperature:184 °c,194°c, 204°c,226°c(As long as the steam temperature you need is lower than 226°c, we can do it).

5.Fuel:coal,biomassa

6.Structure:horizontal water-fire tube, single drum

7.Type:we have two types.One is DZH chain grate stoker automatic feeding fuel and removing dregs type. Another is DZH hand operate moving grate type which needs labour to feed fuel and remove the dregs.

8.Application:industrial production and processing.

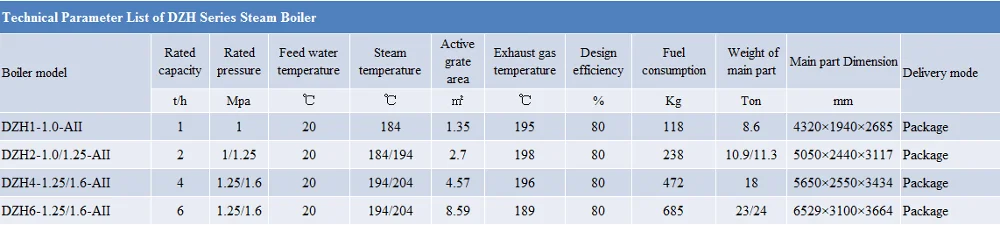

II.Technical datasheet

III. Adventage of Industrial Wood Fired Thermax Steam Boiler

1.Three pass structure.

Function: ectend the flow of smoke and enhance the heat transfer.

2. Water-fire tube type.

Function:Fire tube:the flue goes through furnace, wing-shape flue and fire tubes to form three pass as said in the above.?Water tube: water in some tubes rises after heating and some declines, which forms a natural circulation.

3.Spirally corrugated tube

Function:heat transfer enhancement, reduce the spirally corrugated tube numbers, and improve the suppleness to avoid the tube plate cracking.

4.Arched tube plate

Function:reduce the thermal stress of weld and improve the tube plate suppleness,meantime, simplify the structure and save the boiler room space.

5.Wing-shape flue.

Function:reduce the smoke temperature ??of high temperature tube plate to slow ??down subcooled boiling. In this way, it ??can prevent tube plate cracking, reduce heat ??load of boiler bottom and prevent bulge.

6.Simple circulation loop, large sized down pipe and bottom container. ?

Function: Prevent tube explosion , increase the reliability of water circulation ,avoid deposition of debris and dirt,reduce fuel consumption and improving the operating time of boiler.

7.New type arch made with ?refractory cement by overall pouring and big size furnace.

Function:Reduce fuel consumption and protect the environment.

8.Optimally designed water feeding apparatus and steam separation device.

???Function:The optimally designed water feeding apparatus reduces overhigh water level in shell high temperature zone due to overheat;

9.optimally designed steam separation device is good for gravity separation, which makes the steam humidity lower than 1%, obviously lower than national standard of 4%;

Small overall dimensions and low boiler room investment cost. ??Function: The main heating surface is ??installed in the shell, and a boiler with ??less capacity can cancel the rear heating ??surface. Its overall dimension is obviously ??lower than other furnaces. The boiler below ??100 steam tons (70MW) can be arranged in ??single layer, making the investment of the ??boiler room save more than 50% than other ??furnaces;

10..Complete protection device

Function:deal with the situation of overpressure,overtemperature,water shortage and flameout.

Q: How can you get the best price quickly?

A: We need to know the boiler capacity, the fuel you plan to use and the steam pressure you need, and then we can confirm the boiler model.

Customer needs to provide us your name, email addess and company name, and then we will send you price list imediately. And if you use whatsapp, skype or wechat, you can provide us your ID, it will be more convenient for our communication.

Q: Why should you believe our quality?

A: more than 60 year experience, founed since 1956; Chinese-government appointed Boiler Manufacturer.

With ISO9001certificates.

Quality control system: Include 8 subsystems, design, techonics, welding, inspection, non-destructive testing, heat treatment, materials physics and chemistry inspection, device management Each process will be strict supervised. 5 process quality point, Raw material inspection, product specimen, NDT, hydrostatic test, Heat treatment. The products must be inspected by third party before delivery.

Q: What about the installation?

A: After you receive the boiler, we will guide you to make some preparation for installation; If necessary, our expert will fly to your local place in 72 hours. The experts will responsible for guiding installation,training, trial operation.

Q:What is the using life of your boiler?

Normally the boiler is design for 20 years life span, but with right operation and good maintenance, the boiler can be use 20-25 years.

One-stop service

You only need to provide what you need, and the rest,We will provide product design,manufacturing, transportation, installation team installed faction, guide the operation and so on. We guarantee to provide you with satisfactory service.

Warranty :

1.two-year warranty and full-life service for all our steam boilers.

2.60 years professional boiler manfuacturer since 1956.

3.X-ray test before delivery to guarantee the boiler's excellent quality.

4.NDT test before delivery to assure the boiler's excellent quality.

Accessories and boiler room equipment service:

1.A full range of original spare parts are available for all yuanda boilers.

2.free boiler online installation guidance service.

The factory manufacture situation are as follows: