Brand Name: HTEG

Model Number: Customized

Place of Origin: Shandong, China (Mainland)

Max 8 meter length enameled carbon steel tube for boiler replacement parts

Specification

The air preheater exists the problem of collection of ash , worn down , low temperature corrosion to effect the safe and economical operation for the boiler unit . At the moment , the investment of air preheater is 6%-8% of the whole boiler investment in the industrial boiler and power station boil , due to the problem of collectionof ash, worn down, low temperature corrosion to incur the direct loss of replacing equipment and shuting down is 4~5% of the operation cost and the loss will be more large when the boiler is shut down incurred by this problem .

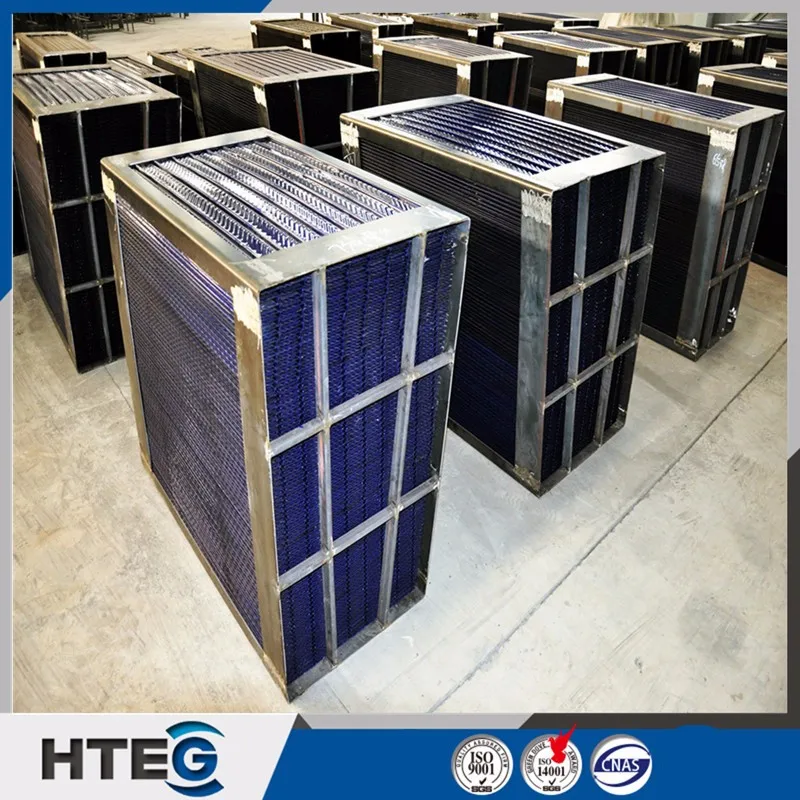

Aim at the above questions,we develop the new heat transfer parts ——Good rubbish burning furnace, biomass boiler used blue colour enamel steel tubes and received 5 patents .

The uniform colour enameled tube is manufactured with the enamel which is our own

developed with the scientific formula and is evenly coated on the surface of the steel tube by

the auto enamel tube production line . To use best temperature change performance enameled tubes as the heat exchange parts will be anti-abrasion and anti-corrosion, the surface is smooth

and low cost of maintenance .

Features

1.The enameled tubes are not easily broken enamel surface, no crack, acid and alkali resistance, resistance to gas erosion, smooth and high, gas flow resistance, easy Fouling;

2. As the flue gas across tube, the flue gas side of the heat capacity of exile to strengthen, under the same heat transfer coefficient (enamel thickness ratio of thermal conductivity with very small, about 0.0002, the calculation is negligible), wall temperature vertical preheater than ordinary steel increased 10-30 Degree Celsius, the overall heat transfer coefficient of about 20.3-24.2W;

3. two horizontal enamel sealing tube box, the sealed tube box structure welded high strength, pipe damaged or the overall change can only block, and heat-packing seal, can only replace the damaged pipe tube, easy maintenance;

4. The preheater is mainly used for boiler preheater, the low temperature.

Applications

To adapt the different boiler burning type, different fuel and different fume ingredient, we developed the below enamel tube air preheaters to fit the different medium:

1. The CFB boiler and coal powder boiler used enamel steel tubes, seam or seamless steel tube with green colour.

2. The rubbish burning furnace, biomass boiler used enamel steel tubes, seam or seamless steel tube with blue colour.

3. The Chain grate and layer burning boiler used enamel steel tubes, seam or seamless steel tube with brown colour.

4. The oil burning boiler, coking boiler and gas boiler used enamel steel tubes,seam or seamless steel tube with dark green.

Related Products

Inquiry now

Our Company

Shandong Hengtao Energy Saving & Environment Protection Co., Ltd. established in 2003, which is specialized in designing, manufacturing, engineering, supplying of boilers, boiler components and boiler auxiliaries. We have 50 senior boiler professional engineers,15 boiler improvement professional and technical teams, more than 100 success cases of boiler energy-saving technological transformation.

Workshop

Our main products including CFB boiler, coal fired boiler and boiler parts such as tubular air pre-heater, rotary air pre-heater, super heater, re-heater, header, membrane water wall and economizer. We are also the provider for boiler integrated energy-saving solutions and we have EPC qualification.

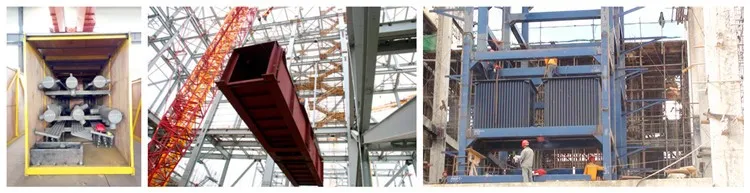

Packing & Shipment

Clients

Hengtao products have been exported to Mongolia, Turkey, Thailand, Vietnam, Indonesia, India, Iran and other oversea countries and areas.

Certifications

Grade A boiler manufacturing; installation and contract of electromechanical equipment; EPC qualification for electric power engineering construction; installation, transformation and maintenance qualification of Grade 1 boiler and A2 pressure vessel manufacturing. We also have ISO, TUV, ASME, SGS ect. certifications.

FAQ