Brand Name: HTEG

Model Number: Customized

Place of Origin: Shandong, China (Mainland)

China Manufacture Industry Boiler Green Colour Enamel steel tubes

Specification:

The China Manufacture Industry Boiler Green Colour Enamel steel tubes is manufactured with the enamel which is developed by our company with the scientific formula and is evenly coated on the surface of the steel tube by the auto enamel tube production line. To use enamel tube as the heat exchange parts will be anti-abrasion and anti-corrosion, the surface is smooth and low cost of maintenance.

Material: carbon steel, corten steel or equivalent

Introduction:

The air preheater exists the problem of collection of ash, worn down, low temperature corrosion to effect the safe and economical operation for the boiler unit. At the moment, the investment for air preheater is 6%-8% of the whole boiler investment in the industrial boiler and power station boil, due to the problem of collection of ash, worn down, low temperature corrosion to incur the direct loss of replacing equipment and shuting down is 4-5% of the operation cost and loss will be more large when the boiler is shut down incurred by this problem.

Aim at the above questions, we established the exclusive enamel research and development center to supply the complete solution and organize the specific research personnel to tackle key problems, and proceed the large quantities of simulated test and operation test to develop the new heat transfer parts ---enamel tubes and received 5 patents.

The enamel steel tube is manufactured with the enamel which is our own developed with scientific formula and is evenly coated on the surface of the steel tube by the auto enamel tube production line. To use enamel tube as the heat exchanger parts will be anti-abrasion and anti-corrosion, the surface is smooth and low cost of maintenance. To adapt the different boiler burning type, different fuel and different fume ingredient, we developed the below enamel tube air preheaters to fit different medium.

Accessory:

The enamel steel tube is manufactured with the enamel which is developed by our company with the scientific formula and is evenly coated on the surface of the steel tube by the auto enamel tube production line. To use enamel tube as the heat exchange parts will be anti-abrasion and anti-corrosion, the surface is smooth and low cost of maintenance.

Material: carbon steel, corten steel or equivalent.

Application:

Other products:

Our company:

Shandong Hengtao Energy Saving & Environment Protection Co., Ltd. established in 2003, which is specialized in designing, manufacturing, engineering, supplying of boilers, boiler components and boiler auxiliaries.

Our main products including CFB boiler, coal fired boiler and boiler parts such as tubular air pre-heater, rotary air pre-heater, super heater, re-heater, header, membrane water wall and economizer. We are also the provider for boiler integrated energy-saving solutions and we have EPC qualification.

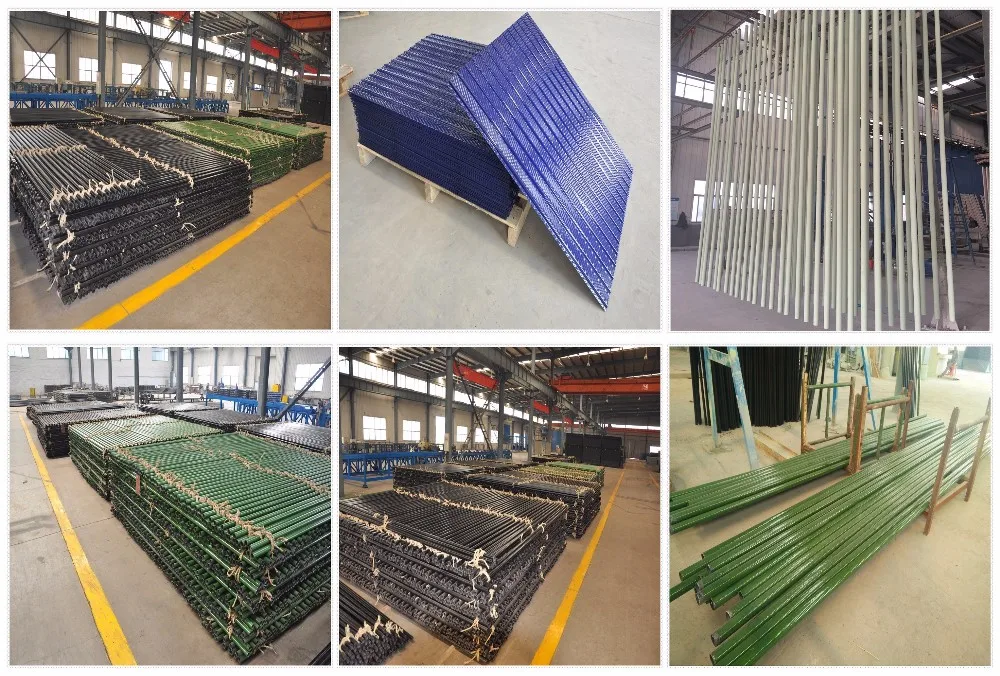

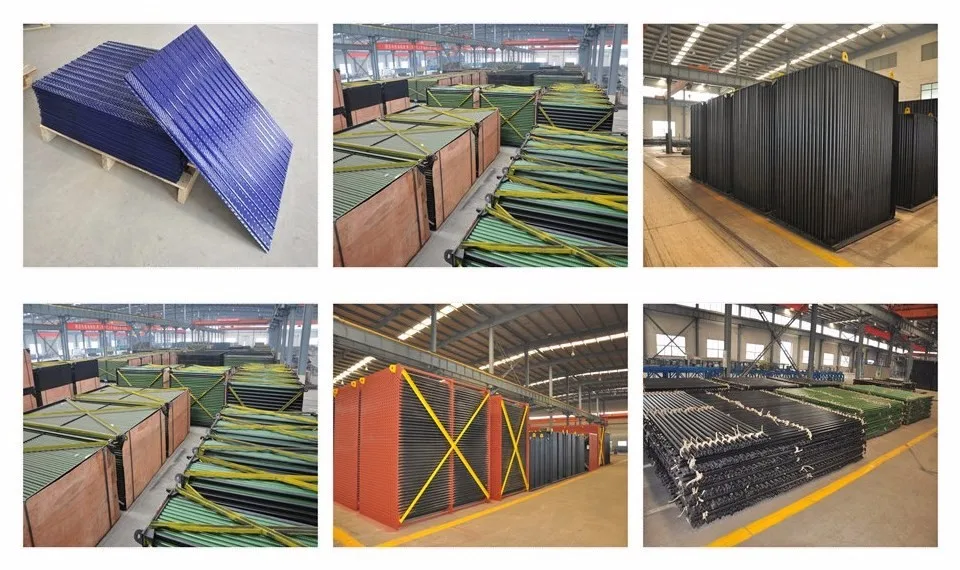

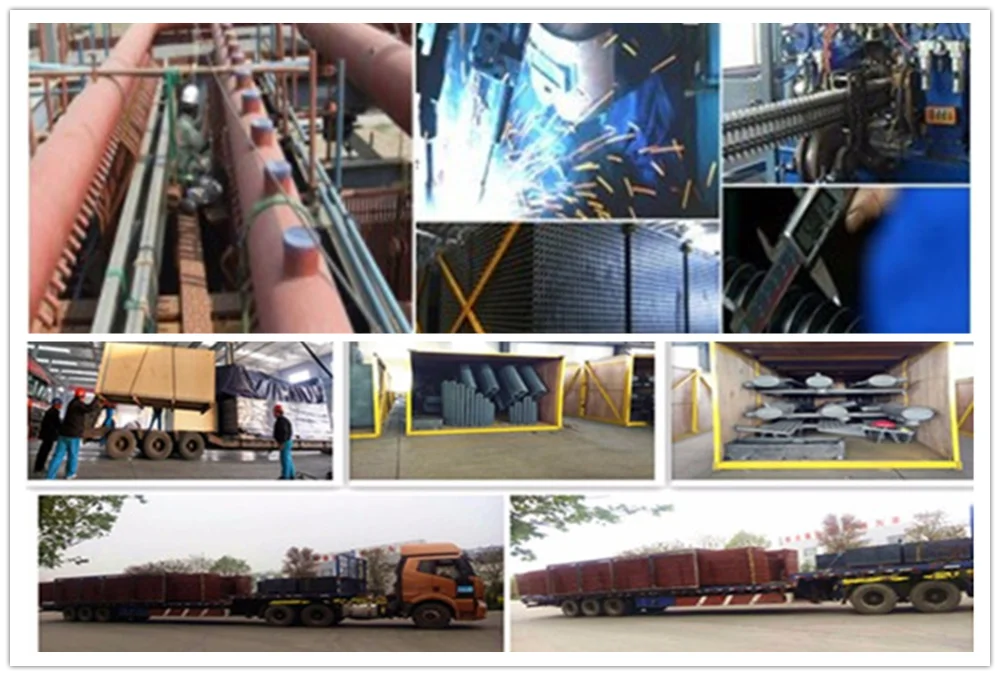

Our workshop&packing&shipment:

Product Line Quality Control:

1. Strength calculation report with applied materials information;

2. 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

3. 100%X-ray inspection report (welding seam): to ensure the quality of the entire boiler;

4. Hydraulic test report: ensure the standard working pressure and safety

Clients:

Cetifications: