Brand Name: China (Mainland) Brand Name

Model Number: A1S003

Place of Origin: Shandong

Product Description

| Product Usage | Silver brazing flux powder can work together with silver based brazing filler metals on copper, copper alloy, stainless steel, nickel alloy, carbide steel, and diamond PCD at the temperature range of 550-850°C in frame brazing, high frequency brazing, electrical resistance welding, furnace brazing, and so on. |

| Physaical Description | White powder, density ≤ 150um |

| Standard | JB/T6045-92, Fluxes for Brazing, Zhuang, Hongshou |

| Components |

KF ;KBF4 ;B2O3 ;Fluoroborate ;Borate ;Activity Agent. Preparation before brazing operation |

| Brazing Opration |

The flux powder should be mixed with water to form a thick paste(mixing rate is 100g powder:35ml water).The paste should then be brushed onto the joint surfaces before brazing.Use a warm brazing rd dipped into flux.Suitable gap for joint is 0.01-0.05mm.Do not overheat the alloy and flux at local area,and heat gradually and evenly using a neutral flame |

| Opration after Brazing | Any or all residue should be removed by hot water .Or it can be soaked in the citric acid |

| Storage | Keep it in dry and cool place. Protect against damp, inedible |

| Package | 500g/can, 500g/bag, 20kg/box |

TiBright has many kinds of product for different utility purposes. We also customerize our product for unique utilities. The following information can not exclusively cover all of our product. Please contact us for details and support.

| Code | Activity range (C) | Description |

| FB102S-10/11 | 550-800 |

General brazing flux with good fluidity, work with silver brasedalloys for brazing steel, steel alloy, stainless steel, tungsten carbide, diamond tools etc. |

| FB102S-21 | 550-800 | Work with high percentage silver brazing alloy for brazing diamond tools, with good fluidity. |

| FB102S-23 | 550-800 |

Work with silver brazing alloys for brazing steel, mild steel, stainless steel, tungsten carbide, diamond tools, etc. Very good fluidity, good physical properties. Integrates the good performance of FB102S-10 and FB102S-21 |

| FB102S-20 | 620-870 | Good fluidity, work with copper based brazing alloys for brazing diamond tools. |

| FB308S | 550-950 | Good fluidity, wide activity temperature range, suitable for brazing high silver brazing alloy. No moisture absorption, no corrosion. |

| FB101S-10 | 650-850 | Suitable for brazing copper and copper alloy, steel and stainless steel, steel tools etc. |

| FB104S | 650-850 | Suitable for brazing copper and copper alloy, steel and stainless steel, tool steel, tungsten carbide etc. Better performance than 101. |

FB102 series is the most commonly used flux product. The following chart is detail comparison of FB102 series product.

|

For low silver component brazing wire, Silver brazing flux FB102 |

|||||||||

|

Parent pieces materials |

Suitable Field |

Oxide layer decompose |

Prevent rexidation |

Fluidity of filling metal |

Corrosivity |

Filling metal attachment |

Brazing gap strength |

Brazing gap air tightness |

|

|

-11 |

Very broad, copper or iron alloys |

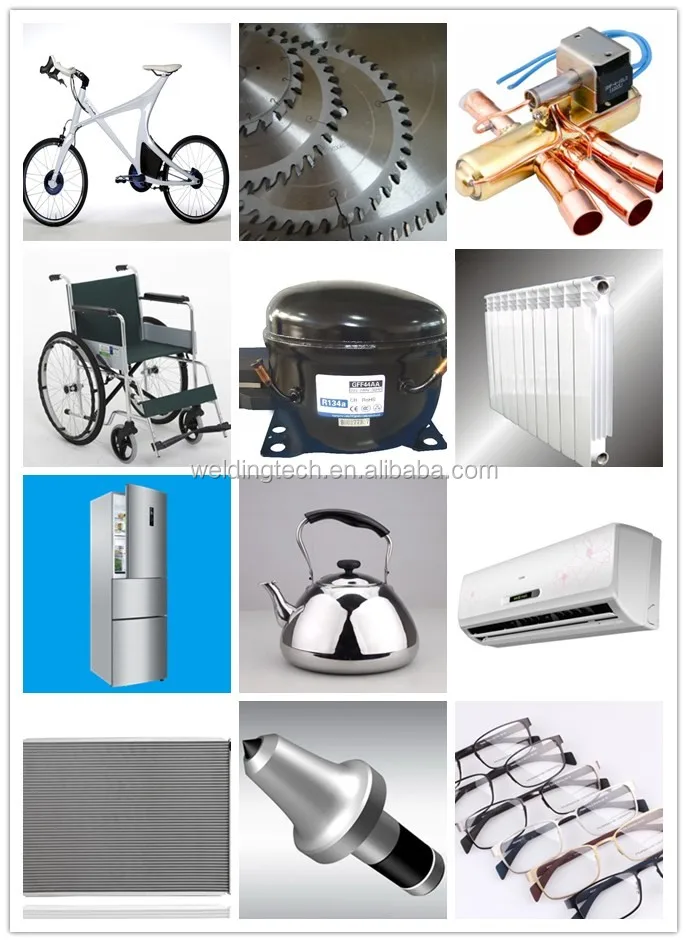

Very broad: electrical devices, cutters, hardware tools, glasses, spectacle frame and so on. |

++ |

++ |

++++ |

+++++ |

+++++ |

+++ |

++++ |

|

-21 |

Better for copper alloys |

Electrical devices: refrigerator, A/C, compressors, and so on |

++++ |

++++ |

++++ |

+ |

+++++ |

+++++ |

++++ |

|

-31 |

Better for steel and red copper |

Heat-exchanger producer, precise military applications |

++++ |

++++ |

+++ |

++ |

+++++ |

+++++ |

++++ |

|

-41 |

Better for stainless steel and red copper |

Automotive, engine, compressors, and so on |

+++++ |

++++ |

++++ |

++ |

+++++ |

+++++ |

++++ |

|

-41C |

Better for stainless steel and brass copper |

A/C accessories |

+++++ |

++++ |

++++ |

++ |

+++++ |

+++++ |

+++++ |

|

-51 |

Better for steel and copper alloys |

Electrical devices: refrigerator, A/C, compressors, and so on |

+++++ |

++++ |

++++ |

+ |

+++++ |

++++ |

++++ |

|

-61 |

Better for copper and copper alloys |

Precise welding, spectacle frame |

+++ |

+++ |

++++ |

++ |

+++++ |

++++ |

++++ |

FAQ

Process Flux

Application

Buying Guides

Yantai TiBright Welding Materials Co. Ltd., founded in 2000, is a professional developer and international supplier of inclusive brazing materials, equipment, and consultant. TiBright has hundreds of products for different applications. Customized products are also available for specific purposes.

When choose from our product library, please check out our recommended product list, If you have any questions, please let us know, We will try our best to satisfy your inquiry. Sometimes we need our customers to try different samples to make the perfect decision. Generally, we need to know the following information to choose a right product for you.

1. Materials of your parenting parts (to-be-brazed parts).

2. Heating methods. (eg. flame, induction, vacuum furnace etc. )

3. Atmosphere of application. (eg. room air, protective inert gas, reductive gas, vacuum, etc.)

4. Dimensions of your parts. Photos or graphs are preferred. (Different dimensions require different procedures.)

5. Current solution. (eg. brazing materials, equipment, procedures, etc.)

6. The reasons of searching new solution. (eg. price, strength, applicability, etc.)

7. Industry of your application. (Help us refer to similar examples.)

Package

Normal package:

Other package can be customized according to customer's requirement.

|

Product |

Dimension |

Package |

|

Brazing Alloy Rod |

500 mm |

1 kg/bag, 20 kg/box,10 kg/bag |

|

Brazing Alloy Rod |

1000 mm |

5 kg/bag, 30 kg/box |

|

Brazing Alloy Wire |

Roll |

5 kg/roll, 10 kg/roll, 20 kg/roll |

|

Brazing Alloy Sheet/Strip |

All kinds |

1 kg/bag, 10 kg/box, 20 kg/box |

|

Brazing Alloy Ring |

All kinds |

1 kg/bag, 10 kg/box, 30 kg/box |

|

Brazing Alloy Powder |

|

5 kg/bag, 10 kg/box, 30 kg/barrel |

|

Brazing Alloy Paste |

|

1 kg/can, 10 kg/barrel, 30 kg/barrel |

|

Brazing Flux Powder |

|

500 g/can, 500 g/bag, 20 kg/box |

|

Brazing Flux Paste |

|

1 kg/can, 1 kg/bag, 40kg/box |

|

Brazing Flux Paste-Auto |

|

1 kg/can, 1.5 kg/can, 9kg/box |

|

Brazing Flux-liqui/gas |

|

3 liter/barrel, 3.5 kg/barrel, 12kg/box, 200 liter/barrel |

Our Services

With hundreds of products in our product library, TiBright is a professional developer and international supplier of inclusive brazing materials, equipment, and consultant.

One highlight of our services is that we provide customized products specially designed for specific customers. We have a lot of successful cases in which the customers had the products suitable for their own procedures, environment and operation routines perfectly.

We also provide entire brazing solution for customers to solve all the problems related to brazing process. We provide consultant for customers with complicated applications and innovative demand.

About sixty percent of our equipment and devices are designed and crafted in our own machine workshop, which engaged us the ability of prompt reaction towards new updates from customers. We also produce specially designed brazing tools and machines. We often develop products together with our customers for their individual needs.

Company Information

Yantai TiBright Welding Materials Co. Ltd. was started from a laboratory in 1996 and founded in 2000. The company is the first one who specialized in brazing materials in China. The pioneers of the company started product formulas from very basic research. With hundreds of products, TiBright has become a professional developer and international supplier of inclusive brazing materials, equipment, and consultant.

As we focus on brazing materials, our main products are brazing fluxes, brazing alloys, self fluxing brazing alloys, brazing alloy paste, and brazing tools. We make brazing alloys with main components of silver, copper, aluminum, nickel, chromium, zinc, tin, manganese, etc. We also make fluxes and binder agents for these alloys.

Since 2010, our research team has been focusing on the brazing alloy powder and paste as well as the self-fluxing alloys, such as flux coated wires and rings, flux cored wires and rings.

In the year 2015, TiBright was asked to be the first draftsman of the industry standard of China "JB 6045-2015, Fluxes for Brazing" and attended the drafting work of many standards as expertise. TiBright’s research team members apply for patents and publish research articles on academia periodicals every year. By 2016, TiBright has been authorized 15 patents.

Our main current customers are in dozens of different industries, such as radiator, compressor, air conditioner, refrigerator, electric, eye glasses, auto parts, cutting tools, kitchen and bathing, medical instruments, nuclear station, and so on. Our famous customers include Haier, Gree, Media, Siemens, Sanhua, and so on.