Brand Name: VENTECH

Model Number: SD-VA, SD-VB

Place of Origin: CHINA

VENTECH, YOUR EXPECT FOR AIR DIFFUSER AND GRILLE

Smooth, quite, comfortable. Existing, but feel like nothing.

Ventech Ventilation diffuser is a device that is designed to provide air flow in a room thoroughly.

It works to increase the efficiency of air conditioning units by distributing cooling air. When an even airflow is maintained, drafts and hotspots in a room are eliminated. Providing greater comfort.

Ventech Ventilation diffuser is a device that is designed to provide air flow in a room thoroughly.

It works to increase the efficiency of air conditioning units by distributing cooling air. When an even airflow is maintained, drafts and hotspots in a room are eliminated. Providing greater comfort.

Ceiling diffusers direct the air from air conditioning systems into the room. The resulting airflow induces high levels of room air, thereby rapidly reducing the airflow velocity and the temperature difference between supply air and room air. Ceiling diffusers allow for large volume flow rates. The result is a mixed flow ventilation in comfort zones, with good overall room ventilation, creating only very little turbulence in the occupied zone.

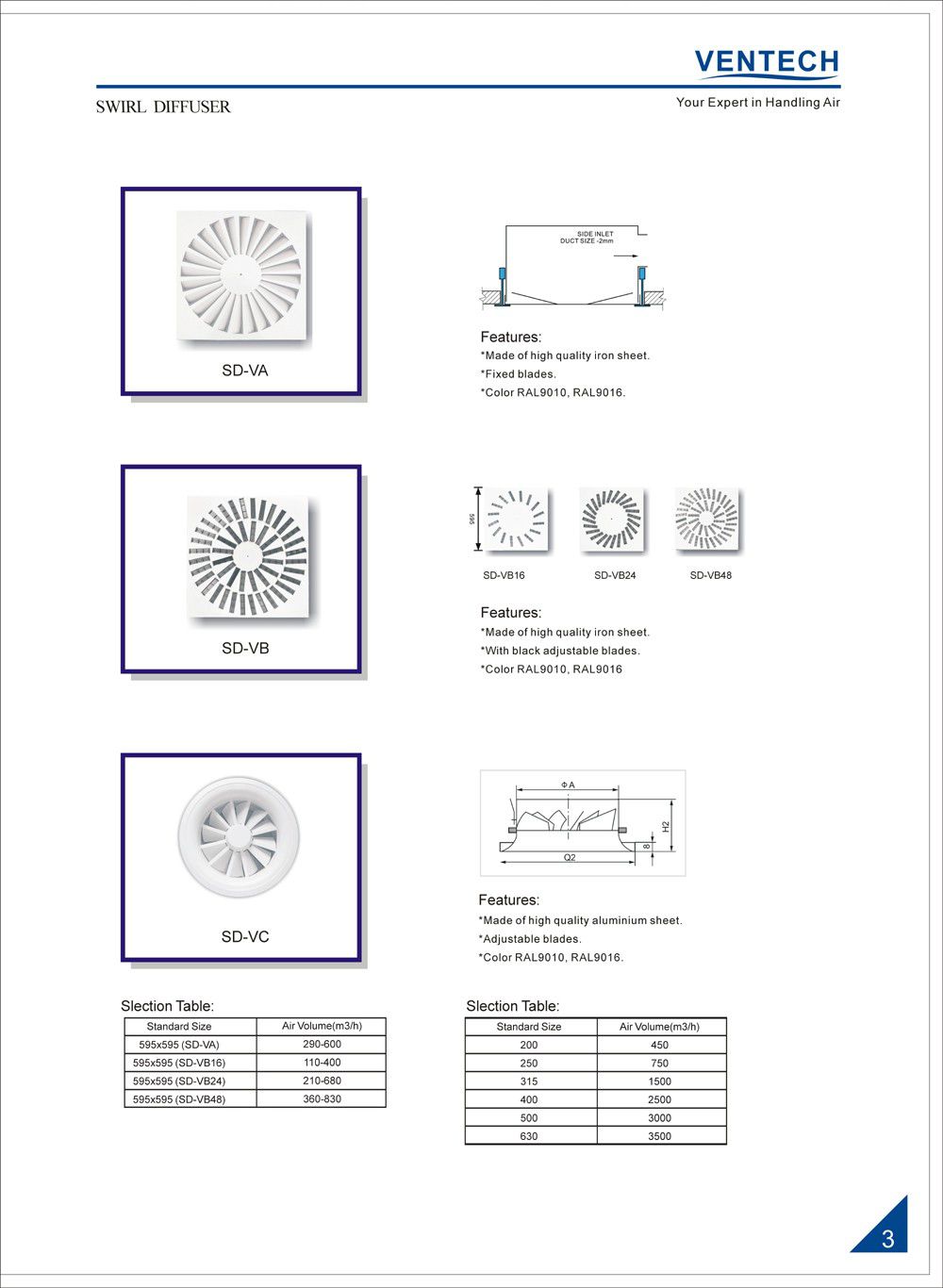

Circular and square ceiling swirl diffusers with fixed air control blades, for high volume flow rates at low sound power levels and low differential pressure due to innovative polymer technology

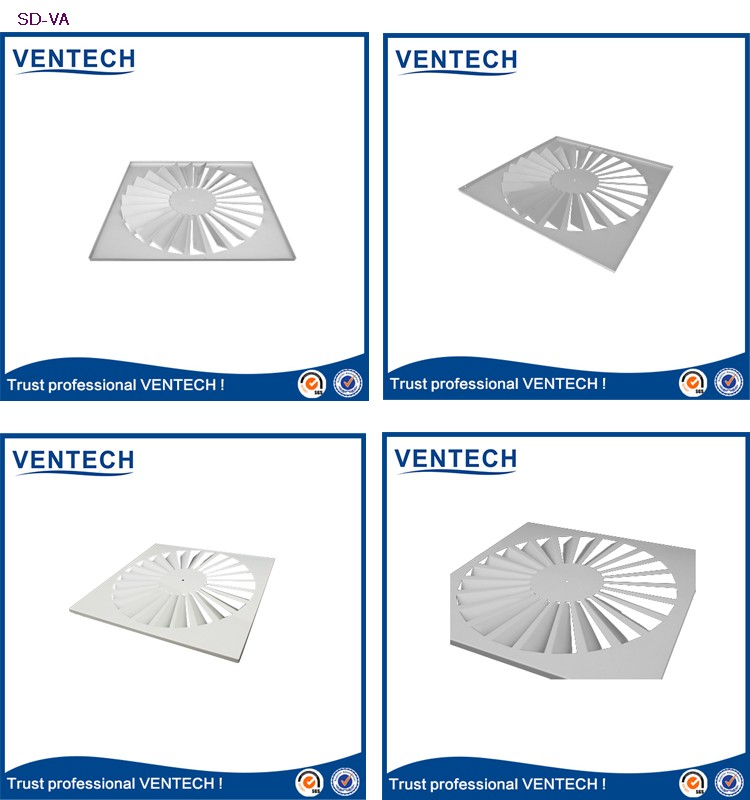

SD-VA. This Model can be made into standard sizes only, made of GI sheet.

SD-VC. This Model can be made into six standard sizes only, made of aluminum.

SD-VC. This Model can be made into six standard sizes only, made of aluminum.

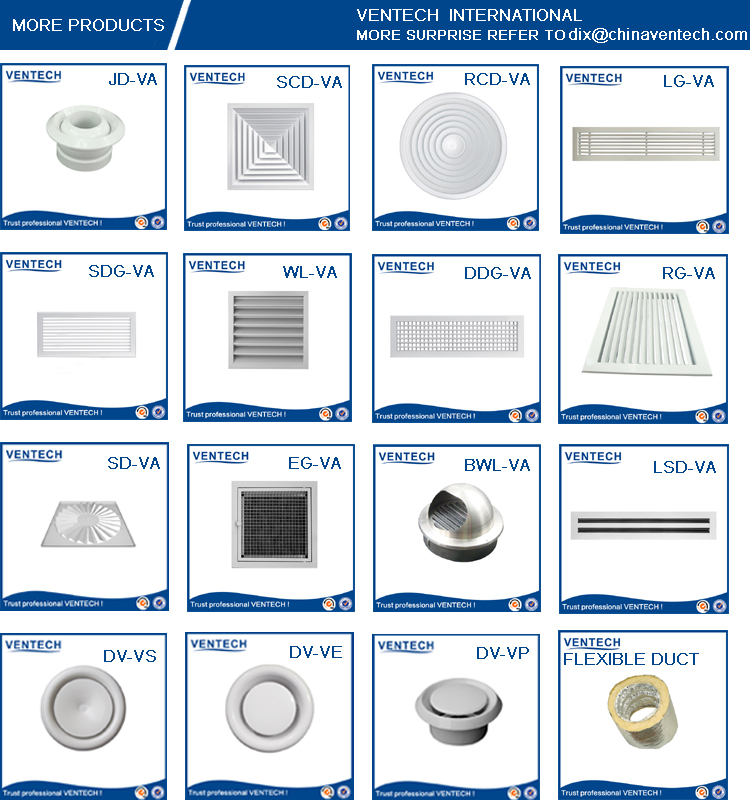

Similar swirl diffuser

SD-VB

SD-VB16

SD-VB24

SD-VB48

What is an swirl diffuser?

Standard sizes as below:

SD-VA, VB, VB16, VB24, VB48

· Face size:595X595MM

· Height: 10mm

SD-VC

· Neck size:200, 250, 315, 400, 500, 630mm

· Height:

How to make a swirl diffuser?

In order to make a high quality circular diffuser, Ventech people introduce a whole production line with advanced stamping, punching machines which are operated by experienced workers.

Before polishing, the air diffuser should be washed for 10mins then baked for 30mins. Power coated is arranged behind the polishing step, by using totally-closed powder finishing line and parching space, the perfect diffuser rolls off the products line and ready to be packed, QC is the priority during each step of the mass productions. We have professional QC to check quality before products go to next step.

Notice: The above accessories are optionals. Without any specified, we deliver the products without any accessories.

· pack in carton, pallect, container.

· square swirl diffuser 10pcs/ctn

· round swirl diffuser 1pc/ctn

high quality brand product VENTECH swirl ceiling return and supply diffuser

high quality brand product VENTECH swirl ceiling return and supply diffuser

high quality brand product VENTECH swirl ceiling return and supply diffuser

high quality brand product VENTECH swirl ceiling return and supply diffuser

high quality brand product VENTECH swirl ceiling return and supply diffuser